filmov

tv

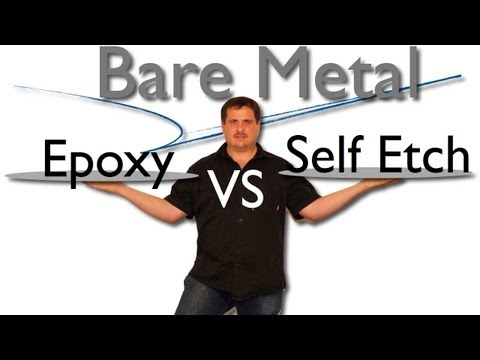

Bare Metal? Which is best? DTM, Epoxy, Urethane, self etch primer, sealer?

Показать описание

in this video I explain the different purposes for most primers out there in the market. The primers include DTM primer , Urethane primer surfacer , high build primer , epoxy primer , primer sealer , self etch aka self etching primer , aerosol primers aka rattle can , krylon , and duplicolor .

If you would like to help support the channel you can do so by using the "Super Thanks" here on YouTube or via Paypal or Cashapp.

Cashapp: $perezjet

Thank you in advance!

If you would like to help support the channel you can do so by using the "Super Thanks" here on YouTube or via Paypal or Cashapp.

Cashapp: $perezjet

Thank you in advance!

Bare Metal? Which is best? DTM, Epoxy, Urethane, self etch primer, sealer?

Bare Metal vs Hypervisor - Which Is Right For Your Project?

Big Misconceptions about Bare Metal, Virtual Machines, and Containers

Bare Metal vs Virtual Machine

Hyve's Bare Metal Servers

Top 10 Bare Metal Server Providers

Bare Metal with a Hypervisor vs. Dedicated Host: What's the difference?

Epoxy Primer vs Self Etch Primer for Bare Metal

E30 325i preface Shadowline restomod

Best Bare Metal Server Providers

How to Choose the Best Bare Metal Server Provider: Top Picks for 2023 - Raksmart

Top 10 Bare Metal Server Providers: Reviews, Features, and Comparisons - Raksmart

How to Remove Surface Rust & Protect Bare Metal - Fast Etch - Eastwood

Bare Metal Polish

Best Bare Metal Cleaner

Best Bare Metal Server Providers

How To Protect Your Bare Metal Hot Rod with Sharkhide Metal Protectant

Easy to Apply Clear Coat! Perfect Bare Metal or Painted Surfaces - Diamond Clear from Eastwood

The PERFECT Chrome Paint for Model Cars! Better Than BARE METAL FOIL?!

FINALLY! Linux on the Macbook M1 (bare-metal)

BONDO ON BARE STEEL VS EPOXY PRIMER | BONDO ON EPOXY | PLASTIC FILLER ON EPOXY | PLASTIC FILLER

You have to use epoxy primer over bare metal. No other way around it.

Spray Can 2K Epoxy Primer For Bare Metal

THE MASTER TEACHES BARE METAL👍 Easy DIY Billy Sander Prep For Self Etching Primer Paint Tips Tricks...

Комментарии

0:19:54

0:19:54

0:01:24

0:01:24

0:07:02

0:07:02

0:02:50

0:02:50

0:01:08

0:01:08

0:04:48

0:04:48

0:05:21

0:05:21

0:09:16

0:09:16

0:16:20

0:16:20

0:00:51

0:00:51

0:01:49

0:01:49

0:02:15

0:02:15

0:00:55

0:00:55

0:01:15

0:01:15

0:04:53

0:04:53

0:00:46

0:00:46

0:35:12

0:35:12

0:02:41

0:02:41

0:02:12

0:02:12

0:14:37

0:14:37

0:08:48

0:08:48

0:00:24

0:00:24

0:04:43

0:04:43

0:01:00

0:01:00