filmov

tv

Pile cap curing

Показать описание

pile and pile cap curing time for removal and loading

i have been working on a pile foundations,

I need to know what will be minimum time required for curing of concrete before

commencement of following works after piling,

2. pile intergrity test

3. pile cap & pedastal concreting.

4. form work removal.

5. pile cap loading with column.

Please let me know also the code which specifies these minimum curing time.

Recommended for you

2. pile intergrity test

3. pile cap & pedastal concreting.

4. form work removal.

5. pile cap loading with column.

CIP Conc piles are normally cast to the required 'cut-off' elevation. Precast and steel can be cut off at time of installation, except they can be checked prior to cut off if there are adjacent piles to be driven.

Except for micropiles and odd installations, it is not common to do an integrity test in these locales.

Pile caps can be installed within a couple of days of pile installation.

I usually have the contractor loosen the forms after a day and allow removal after 3 days.

Pile cap loading can occur within a week. Care to make sure anchor rods are not damaged by early loading.

Full design load should be after 28 days... longer time the better for long term movements.

METHOD STATEMENT OF PILE CAP

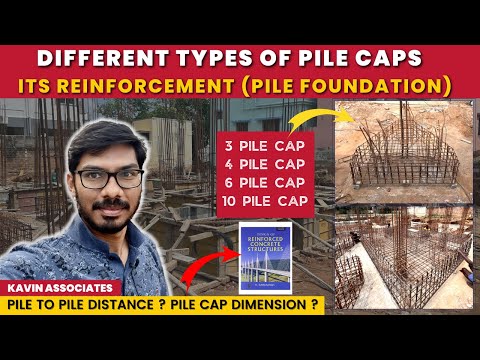

A pile cap is a thick concrete foundation rest on concrete or timber piles that have been driven into soft or unstable ground to provide a stable foundation. It usually forms part of the foundation of a building or structure or it is the uppermost portion of a pile which acts to secure the piles in position and receive and distribute superstructure loads.

In this article we will discuss the method statement of pile cap in detail with the help of following section:

Equipment

Procedure

Safety

1.EQUIPMENT

Excavator

Dumpers

Batching Plant

Transit Mixers

Truck / trailer

Welding Generator

Concrete Vibrators

Concrete Needles

Jack hammer

Compressor

Crane / Hydra

De-watering Pump

* As per site condition above mentioned equipment can be increased or decreased.

2.Procedure

a.SURVEY:

Before commencing excavation, the pile cap area shall be marked on the ground after carrying out survey with reference to control points. After excavation the levels of the pit shall be checked for correctness to the drawings and recorded. Longitudinal and transverse centerlines shall be marked outside the pit for reference for cross checking the pile. The shift of pile shall be recorded by marking the theoretical coordinates of pile on ground and circle of equivalent to pile diameter shall be drawn and shift of actual pile will be measured from theoretical edges of pile. The as built details of the piles shall be recorded jointly. Based on shifted location of pile top, pile Cap / P.C.C. layout shall be marked to ensure minimum 150 mm offset from outer edge of pile. After laying of PCC, the layout of the pile cap shall be marked on it with reference to the reference points to facilitate tying of rebar and erection of shuttering.

b.EXCAVATION:

Shoring shall be provided depending upon the stability of the soil found in the area. Shoring shall be done with the help of old steel plates and props. At road locations the pit shall be excavated to the dimensions providing working space all around the pile cap, to facilitate fixing of steel & erection of shuttering as detailed in the drawings. The last 300 mm excavation shall be carried out manually & leveling course shall be laid down within 36 hrs after completing excavation of last 200 mm depth. Provision for sump shall be made at the comer of the pit to pump out underground water of about 750 mm deep from PCC bottom. Also an earthen drain of about 200 mm width if required shall be provided all around pile cap dimension & it shall be connected with sump to drain off excess rain water/seepage water to ensure that the water table will at least 300 mm below the lowest level of the excavation before laying PCC. The excavated earth shall be then dispo

c.REMOVAL OF LAITANCE:

After excavation the laitance of the piles shall be removed by using Pneumatic Jack Hammers seven days after casting of pile or manually three days after casting of pile. The top of pile after striping shall project 50 mm into the pile cap and reinforcements of pile shall be fully anchored in pile cap as per clause 709.5.2 of IRC: 78:2000. The debris of broken concrete shall be removed from the pit and disposed off to approve dumping sites. Exposed bars shall be straightened & cleaned properly with wire brush.

d. PCC:

After leveling the bottom of the bed, sprinkle some water to keep the soil moist. PCC of Mix M15 or specified in drawing shall be mixed at the centralized batching plant at the casting yard and transported to site in transit mixers. The concrete shall directly pour through chutes from three locationslocations.

i have been working on a pile foundations,

I need to know what will be minimum time required for curing of concrete before

commencement of following works after piling,

2. pile intergrity test

3. pile cap & pedastal concreting.

4. form work removal.

5. pile cap loading with column.

Please let me know also the code which specifies these minimum curing time.

Recommended for you

2. pile intergrity test

3. pile cap & pedastal concreting.

4. form work removal.

5. pile cap loading with column.

CIP Conc piles are normally cast to the required 'cut-off' elevation. Precast and steel can be cut off at time of installation, except they can be checked prior to cut off if there are adjacent piles to be driven.

Except for micropiles and odd installations, it is not common to do an integrity test in these locales.

Pile caps can be installed within a couple of days of pile installation.

I usually have the contractor loosen the forms after a day and allow removal after 3 days.

Pile cap loading can occur within a week. Care to make sure anchor rods are not damaged by early loading.

Full design load should be after 28 days... longer time the better for long term movements.

METHOD STATEMENT OF PILE CAP

A pile cap is a thick concrete foundation rest on concrete or timber piles that have been driven into soft or unstable ground to provide a stable foundation. It usually forms part of the foundation of a building or structure or it is the uppermost portion of a pile which acts to secure the piles in position and receive and distribute superstructure loads.

In this article we will discuss the method statement of pile cap in detail with the help of following section:

Equipment

Procedure

Safety

1.EQUIPMENT

Excavator

Dumpers

Batching Plant

Transit Mixers

Truck / trailer

Welding Generator

Concrete Vibrators

Concrete Needles

Jack hammer

Compressor

Crane / Hydra

De-watering Pump

* As per site condition above mentioned equipment can be increased or decreased.

2.Procedure

a.SURVEY:

Before commencing excavation, the pile cap area shall be marked on the ground after carrying out survey with reference to control points. After excavation the levels of the pit shall be checked for correctness to the drawings and recorded. Longitudinal and transverse centerlines shall be marked outside the pit for reference for cross checking the pile. The shift of pile shall be recorded by marking the theoretical coordinates of pile on ground and circle of equivalent to pile diameter shall be drawn and shift of actual pile will be measured from theoretical edges of pile. The as built details of the piles shall be recorded jointly. Based on shifted location of pile top, pile Cap / P.C.C. layout shall be marked to ensure minimum 150 mm offset from outer edge of pile. After laying of PCC, the layout of the pile cap shall be marked on it with reference to the reference points to facilitate tying of rebar and erection of shuttering.

b.EXCAVATION:

Shoring shall be provided depending upon the stability of the soil found in the area. Shoring shall be done with the help of old steel plates and props. At road locations the pit shall be excavated to the dimensions providing working space all around the pile cap, to facilitate fixing of steel & erection of shuttering as detailed in the drawings. The last 300 mm excavation shall be carried out manually & leveling course shall be laid down within 36 hrs after completing excavation of last 200 mm depth. Provision for sump shall be made at the comer of the pit to pump out underground water of about 750 mm deep from PCC bottom. Also an earthen drain of about 200 mm width if required shall be provided all around pile cap dimension & it shall be connected with sump to drain off excess rain water/seepage water to ensure that the water table will at least 300 mm below the lowest level of the excavation before laying PCC. The excavated earth shall be then dispo

c.REMOVAL OF LAITANCE:

After excavation the laitance of the piles shall be removed by using Pneumatic Jack Hammers seven days after casting of pile or manually three days after casting of pile. The top of pile after striping shall project 50 mm into the pile cap and reinforcements of pile shall be fully anchored in pile cap as per clause 709.5.2 of IRC: 78:2000. The debris of broken concrete shall be removed from the pit and disposed off to approve dumping sites. Exposed bars shall be straightened & cleaned properly with wire brush.

d. PCC:

After leveling the bottom of the bed, sprinkle some water to keep the soil moist. PCC of Mix M15 or specified in drawing shall be mixed at the centralized batching plant at the casting yard and transported to site in transit mixers. The concrete shall directly pour through chutes from three locationslocations.

0:03:42

0:03:42

0:03:41

0:03:41

0:00:16

0:00:16

0:04:53

0:04:53

0:00:11

0:00:11

0:01:56

0:01:56

0:00:09

0:00:09

0:00:11

0:00:11

0:00:08

0:00:08

0:08:57

0:08:57

0:00:16

0:00:16

0:00:16

0:00:16

0:00:10

0:00:10

0:00:16

0:00:16

0:00:17

0:00:17

0:11:21

0:11:21

0:00:16

0:00:16

0:00:28

0:00:28

0:00:12

0:00:12

0:00:10

0:00:10

0:00:16

0:00:16

0:00:22

0:00:22

0:00:07

0:00:07

0:08:25

0:08:25