filmov

tv

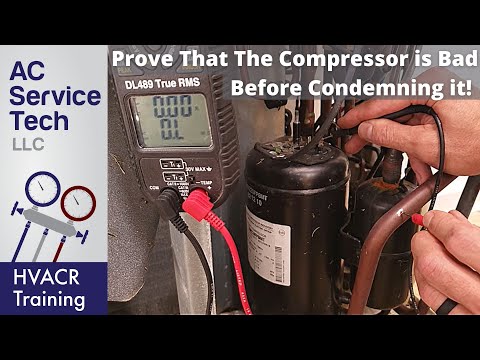

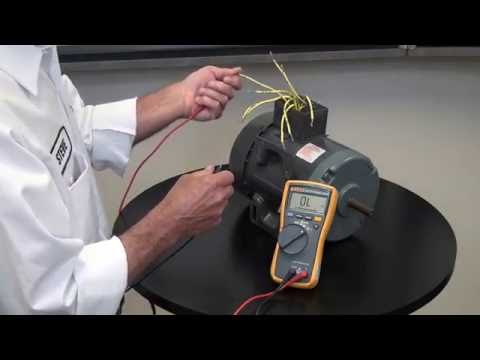

How to check the windings of a refrigeration compressor

Показать описание

Describes the use of an ohmmeter to check the windings of a single phase air conditioning compressor motor. Includes winding resistance and check for shorts to ground

If you are a homeowner looking to repair your own appliance, understand that the voltages can be lethal, the fuels are highly flammable and high pressures are used. Know your limits.

If you are a homeowner looking to repair your own appliance, understand that the voltages can be lethal, the fuels are highly flammable and high pressures are used. Know your limits.

Using a multimeter to check the windings of a motor .. #SPENDINGELECTRICALTIPS

How to check the windings of a refrigeration compressor

Groschopp Tech Tips | How to Check for a Damaged Armature

Checking Windings in a 9 Lead 3 Phase Motor

HVAC-How To Check The Windings Of a 3 Phase Compressor & Check For Any Grounds (A/C & Refrig...

Understanding electric motor Windings!

how to test 3 phase motor with multimeter

How to Find Common, Start, and Run on a PSC Compressor Motor

How To Troubleshoot 3 Phase Motor With A MultiMeter (3 Phase Motor Test) Winding Resistance Test Ohm

Testing the windings of a motor to check its balanced. #sparky #motor #engineering #electricalwork

How to check if the windings are good on a ECM motor #hvac

Learn to Check All Faulty Contactor by using Multimeter | contactor repairing @TheElectricalGuy

How to Meg a Motor with a Megohmeter - Checking Motor Condition

Troubleshooting 4' Submersible Motor: Insulation & Windings Resistance

[LG Parts] How to check the compressor windings of a refrigerator

PAANO MAG CHECK NG WINDINGS NG 3PHASE MOTOR GAMIT ANG MULTIMETER

Check Compressor Windings With The Insulation Tester - Fluke 1507

Testing if an HVACR Compressor is Shorted to Ground, Open, or Overload Tripped!

how to check motor windings with an LED

How to check a 3 phase motor system

How To Check 3 Phase Power

How to Troubleshoot Submersible Motors with Your Ohmmeter

Identifying 230 and 460 Connections - York Repair Inc

how to check motor pump shorted windings

Комментарии

0:00:10

0:00:10

0:04:23

0:04:23

0:02:51

0:02:51

0:07:55

0:07:55

0:03:49

0:03:49

0:07:51

0:07:51

0:05:59

0:05:59

0:03:11

0:03:11

0:09:26

0:09:26

0:00:47

0:00:47

0:00:19

0:00:19

0:06:42

0:06:42

0:02:44

0:02:44

0:11:37

0:11:37

![[LG Parts] How](https://i.ytimg.com/vi/4XB5QyC3StQ/hqdefault.jpg) 0:01:21

0:01:21

0:16:16

0:16:16

0:04:25

0:04:25

0:11:06

0:11:06

0:03:00

0:03:00

0:05:06

0:05:06

0:01:17

0:01:17

0:03:42

0:03:42

0:02:51

0:02:51

0:00:41

0:00:41