filmov

tv

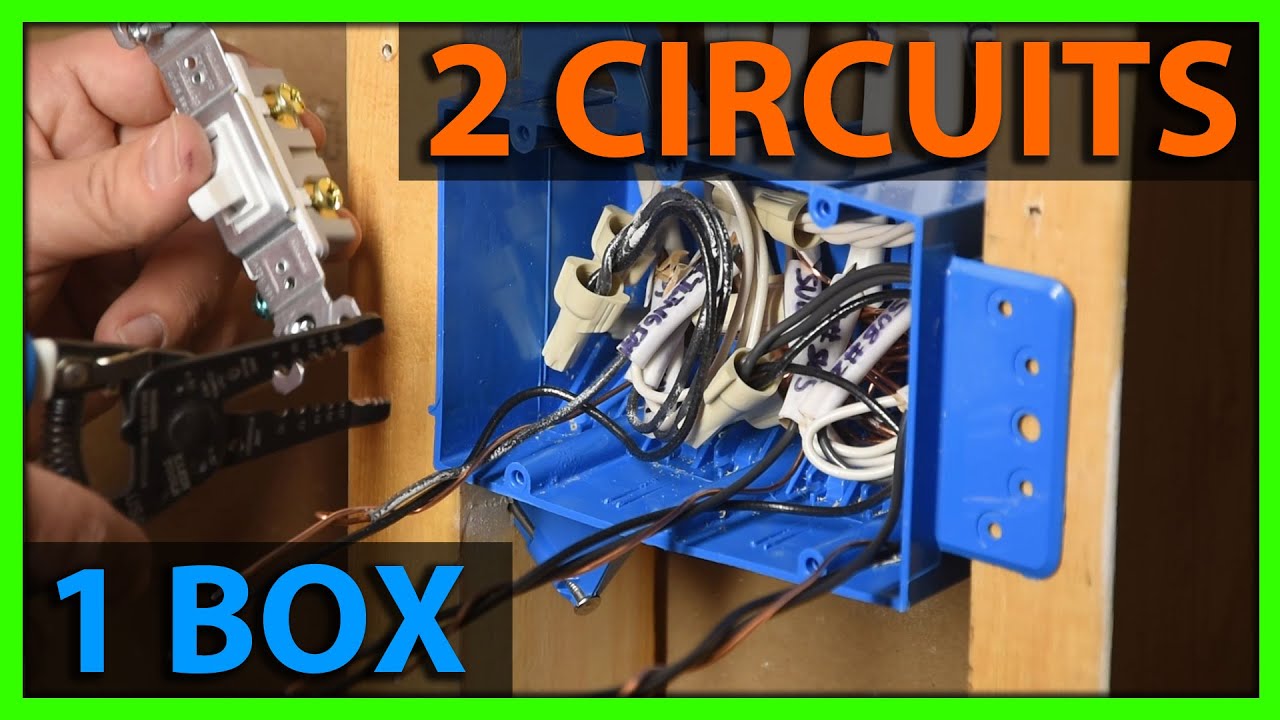

How To Wire a 3 Gang Switch Box With 2 Circuits

Показать описание

Here we go through the step by step process of wiring a triple gang switch box that is being fed from two separate circuits. There are a few additional things that you need to keep in mind when working in a box like this in order to keep everything wired correctly.

0:00 - 3 Gang Switch Box With 2 Circuits

0:20 - Trim Cables & Strip Sheathing

1:20 - Keep Circuits Separate With Labels

3:40 - Tie Only Ground Wires Together

6:28 - Neutrals On Main #6

8:21 - Hot Wires On Main #6

10:14 - Neutrals On Sub #2

11:08 - Hot Wires On Sub #2

12:38 - Basic Electricity Explanations

14:22 - How To Install Single Pole Switch

15:58 - Testing The Circuit

17:45 - SUBSCRIBE!!!

Thanks for watching and subscribing! As an Amazon affiliate I earn from qualifying purchases. Thank you for your support!

Blessings from Minnesota,

Ben

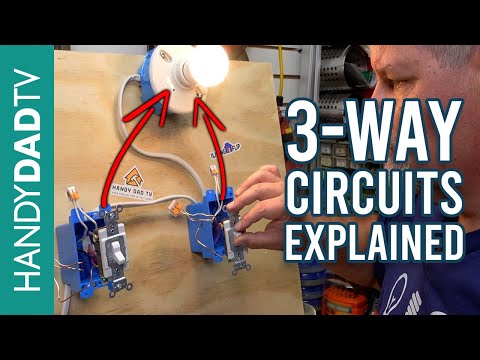

How to Wire a 3-Way Switch

3 Way Switches Explained - How to wire 3 way light switch

How To Wire A 3-Way Switch System Explained! (2022) | Video For Beginners DIY Step By Step Tutorial!

How to wire a 3-way switch system

How to wire 3-way circuits

How To Wire A 3 Way Light

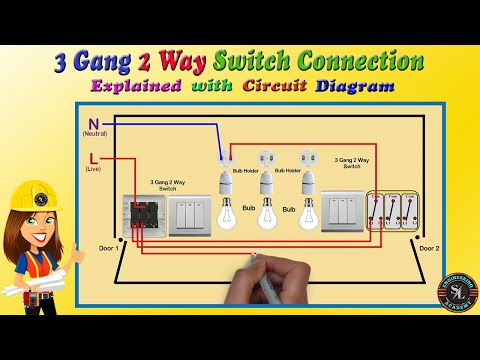

3 Gang 2 Way Switch Connection / How to Wire Three Gang Two Way Switch/ Explain with Circuit Diagram

How To Wire A 3-Way Light Switch - 3 Way Switch Explained (2 EASY & SIMPLE Methods)

How to wire a 3-way switch/4-way switch system

How to wire a 3-way switch

How to Wire 3 Way Light Switches

HOW TO WIRE 3 PRONG ROCKER LED SWITCH

3-WAY Switch fully Explained: How to Wire a 3 Way Light Switch, Identify ALL Wires, Troubleshooting

How To Wire 3 Switches With One Power Source | Install Multiple Light Switches In One Box

How to wire a three-way light switch

How To Wire a 3 Gang Switch Box With 2 Circuits

How To Wire a 3-Way Switch System

3-way switch, how to identify wires-Learn how to wire a three-way switch

Episode 3 - How To Wire For and Install A Switch

How Do I Replace a 3-Way Switch? Which Wire Goes Where??

DIY: How To Wire A 3 Way Switch (Multiple Lights) - IN 5 MINUTES!

2 wire - 3 wire - 4 wire Transmitter wiring connections ||Transmitter Power Supply connection detail

Basic Motor Control: 3 Wire Start Stop Circuit (updated)

Two Way Switching Explained - How to wire 2 way light switch

Комментарии

0:03:54

0:03:54

0:08:27

0:08:27

1:01:22

1:01:22

0:05:30

0:05:30

0:10:10

0:10:10

0:14:54

0:14:54

0:03:38

0:03:38

0:20:37

0:20:37

0:06:53

0:06:53

0:02:40

0:02:40

0:12:01

0:12:01

0:05:22

0:05:22

0:18:07

0:18:07

0:08:02

0:08:02

0:01:22

0:01:22

0:17:26

0:17:26

0:16:28

0:16:28

0:07:10

0:07:10

0:28:22

0:28:22

0:07:17

0:07:17

0:05:36

0:05:36

0:04:31

0:04:31

0:07:43

0:07:43

0:07:05

0:07:05