filmov

tv

How to Fuse Pipe with a McElroy TracStar® 618

Показать описание

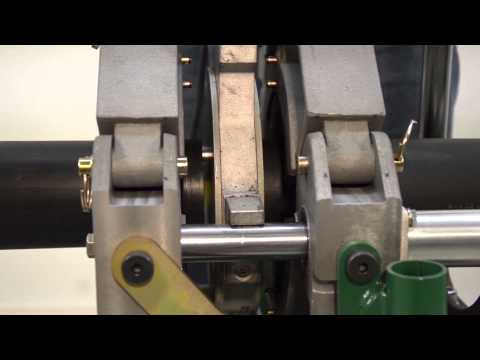

In this video, we show you how to fuse 12-inch IPS pipe with a McElroy TracStar® 618. To fuse 12-inch pipe, McElroy butt fusion inserts are required.

McElroy's 618 line of fusion machines will butt fuse pipe sizes from 6" IPS to 18" OD (180mm to 450mm). They come in multiple model configurations to meet the demands of your pipeline project. All units incorporate the interchangeable 618 four-jaw carriage, which can be easily removed for in-ditch fusion. For tight installations, the outer fixed jaw and skid can be removed from the carriage converting it to a 3-jaw carriage for an even more compact fusion unit. These machines can fabricate segmented ells with optional mitered inserts and are DataLogger® compatible.

The TracStar 618 offers these great benefits:

• Self-contained, self-propelled, all-terrain

• Powered by a 20-HP liquid-cooled diesel engine

• Carriage can be easily removed for in-ditch use

• On-board generator for powering heater and other devices

• Dual hydraulic pipe lifts aid in handling pipe

• Fits in a standard long-box truck bed for easy transport

• DataLogger® compatible

An Automated TracStar is also available.

Version 1.0. 032013

es:wGy2tJIwJgA;

McElroy's 618 line of fusion machines will butt fuse pipe sizes from 6" IPS to 18" OD (180mm to 450mm). They come in multiple model configurations to meet the demands of your pipeline project. All units incorporate the interchangeable 618 four-jaw carriage, which can be easily removed for in-ditch fusion. For tight installations, the outer fixed jaw and skid can be removed from the carriage converting it to a 3-jaw carriage for an even more compact fusion unit. These machines can fabricate segmented ells with optional mitered inserts and are DataLogger® compatible.

The TracStar 618 offers these great benefits:

• Self-contained, self-propelled, all-terrain

• Powered by a 20-HP liquid-cooled diesel engine

• Carriage can be easily removed for in-ditch use

• On-board generator for powering heater and other devices

• Dual hydraulic pipe lifts aid in handling pipe

• Fits in a standard long-box truck bed for easy transport

• DataLogger® compatible

An Automated TracStar is also available.

Version 1.0. 032013

es:wGy2tJIwJgA;

Комментарии

0:09:12

0:09:12

0:07:48

0:07:48

0:03:20

0:03:20

0:10:15

0:10:15

0:11:01

0:11:01

0:08:06

0:08:06

0:07:52

0:07:52

0:08:13

0:08:13

1:22:23

1:22:23

0:08:24

0:08:24

0:03:57

0:03:57

0:00:16

0:00:16

0:01:40

0:01:40

0:15:28

0:15:28

0:00:35

0:00:35

0:00:19

0:00:19

0:01:21

0:01:21

0:00:09

0:00:09

0:00:49

0:00:49

0:00:44

0:00:44

0:00:31

0:00:31

0:01:01

0:01:01

0:00:36

0:00:36

0:00:25

0:00:25