filmov

tv

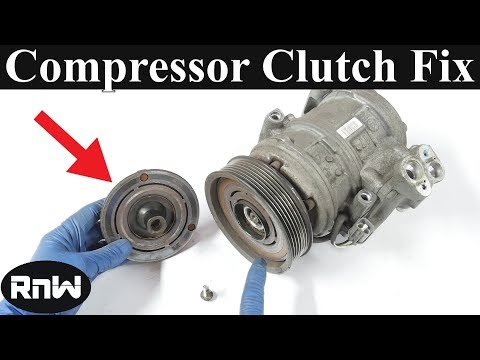

A/C Compressor Clutch and Bearing Replacement. (All Makes & Models)

Показать описание

A/C Compressor Clutch and Bearing Replacement for all makes and models. These A/C compressor clutches all function the same way. A electromagnet pulls on a plate to engage the A/C. Typical failures are, the bearing, or the coil in the electromagnet go bad. The A/C will not work if the clutch is not working correctly. To diagnose an electrical problem with the clutch assembly, the easiest test to do would be, Ohm out the wires going to the electromagnet. The other easy thing to check would be clutch air gap. If the gap is too wide the clutch will not work correctly and the A/C will not work.

Tools:

Help support the channel, buy using my Amazon links

As an Amazon Associate I earn from qualifying purchases and your cost is exactly the same.

Disclaimer:

The information, demonstration and any content contained in this video is for informational purposes only. The user Repair Geek makes no warranty, express or implied, regarding the effectiveness or safety of the contents of this video. In no way should the contents of the video, including the tools used, be repeated or tried by anyone. Viewers should only seek the help of a trained professional located at a licensed auto repair shop for any fix, modification, alteration, or any change to their vehicle. Repair Geek shall not be liable for any injury, damage, or loss to any person or property that may result from use of the tools, equipment, or any content contained in this video. In addition, there is no way to guarantee that the video is not altered or modified or is not in the final form submitted by Repair Geek and therefore, Repair Geek does not warrant that the video is unaltered or not modified. The links on this video to products are for informational purposes only and in no way are an endorsement of the safety or effectiveness of the particular product. Viewers understand that anything contained in this video or linked to or from this video is the sole responsibility of the viewer and in no way provides an express or implied warranty as to the safety or effectiveness of any linked tool, product, or video. Therefore, viewer agrees to release, waive, and discharge Repair Geek or anyone affiliated with Repair Geek, from any and all liability, claims, demands, actions, and causes of action whatsoever arising out of or related to any loss, damage, or injury, including death, that may be sustained by the viewer, or to any property belonging to viewer, regardless of whether the loss is linked to the use of the contents of this video, or otherwise and regardless of whether such liability arises in tort, contract, strict liability, or otherwise, to the fullest extent allowed by law.

Tools:

Help support the channel, buy using my Amazon links

As an Amazon Associate I earn from qualifying purchases and your cost is exactly the same.

Disclaimer:

The information, demonstration and any content contained in this video is for informational purposes only. The user Repair Geek makes no warranty, express or implied, regarding the effectiveness or safety of the contents of this video. In no way should the contents of the video, including the tools used, be repeated or tried by anyone. Viewers should only seek the help of a trained professional located at a licensed auto repair shop for any fix, modification, alteration, or any change to their vehicle. Repair Geek shall not be liable for any injury, damage, or loss to any person or property that may result from use of the tools, equipment, or any content contained in this video. In addition, there is no way to guarantee that the video is not altered or modified or is not in the final form submitted by Repair Geek and therefore, Repair Geek does not warrant that the video is unaltered or not modified. The links on this video to products are for informational purposes only and in no way are an endorsement of the safety or effectiveness of the particular product. Viewers understand that anything contained in this video or linked to or from this video is the sole responsibility of the viewer and in no way provides an express or implied warranty as to the safety or effectiveness of any linked tool, product, or video. Therefore, viewer agrees to release, waive, and discharge Repair Geek or anyone affiliated with Repair Geek, from any and all liability, claims, demands, actions, and causes of action whatsoever arising out of or related to any loss, damage, or injury, including death, that may be sustained by the viewer, or to any property belonging to viewer, regardless of whether the loss is linked to the use of the contents of this video, or otherwise and regardless of whether such liability arises in tort, contract, strict liability, or otherwise, to the fullest extent allowed by law.

Комментарии

0:15:56

0:15:56

0:08:53

0:08:53

0:10:24

0:10:24

0:10:24

0:10:24

0:28:26

0:28:26

0:07:54

0:07:54

0:18:14

0:18:14

0:02:28

0:02:28

0:09:38

0:09:38

0:04:55

0:04:55

0:12:08

0:12:08

0:08:38

0:08:38

0:00:55

0:00:55

0:00:31

0:00:31

0:00:41

0:00:41

0:07:36

0:07:36

0:07:42

0:07:42

0:04:32

0:04:32

0:28:32

0:28:32

0:06:43

0:06:43

0:08:13

0:08:13

0:05:06

0:05:06

0:16:53

0:16:53

0:13:22

0:13:22