filmov

tv

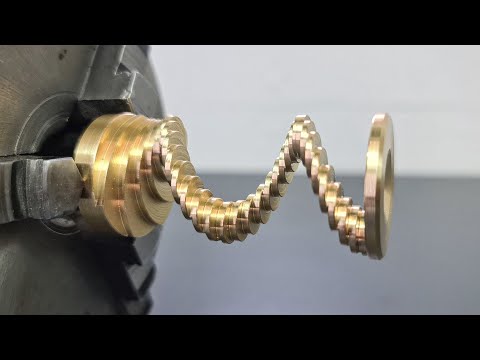

'Zero Tolerance Machining' with the Wire EDM, Making a Puzzle Cube - Part 2 | US Digital

Показать описание

Our machine shop can cut metal so precisely using our wire EDM that two parts fit together with virtually no gap between. Learn even more about how the process works in our follow up video.

These puzzle pieces are not for sale.

#machining #manufacturing #wireEDM

These puzzle pieces are not for sale.

#machining #manufacturing #wireEDM

'Zero Tolerance Machining' with the Wire EDM, Making a Puzzle Cube - Part 2 | US Digital

How these impossibly thin cuts are made

SECRET Process Of MACHINING FLAWLESS Parts

I Machined a 50 Million Dollar Part

'Zero Tolerance Machining' with the Wire EDM - Part 1 | US Digital #Shorts

Zero Tolerance Machining #short

Amazing Extreme Precision CNC Made Metal Block You Never Seen By Jingdiao

Zero Tolerance Machining Compilation

Making The Most Accurate PUZZLE - Zero Tolerance Machining

INVISIBLE CUT Zero Tolerance Machining with Wire EDM

Making a Crazy Part on the Lathe - Manual Machining

What is the closest tolerance you ever worked to? #satisfying #machining

Zero Tolerance Machining Example KBlock

Is Jade Hard Enough to Machine Metal?

wire edm machine

INSANE Tapered Cut on Wire EDM #shorts

This Part is so Difficult, They Told Me It COULDN'T Be Done

Zero Tolerance Machining' with the Wire EDM

We got the MOST ADVANCED WIRE EDM in the World

99% People Satisfying When See This CNC Working Process. Perfect Machines Technology

Zero Tolerance Machining || Awesome 😎

Zero Tolerance Machining 🤯

Zero Tolerance CNC Milled Part

How Zero Tolerance Machining Works Engineering Masterpiece (📸: theukmachinist_)

Комментарии

0:02:55

0:02:55

0:09:37

0:09:37

0:06:34

0:06:34

0:05:44

0:05:44

0:00:57

0:00:57

0:00:36

0:00:36

0:02:14

0:02:14

0:00:45

0:00:45

0:13:26

0:13:26

0:00:48

0:00:48

0:04:15

0:04:15

0:00:21

0:00:21

0:00:14

0:00:14

0:08:23

0:08:23

0:00:16

0:00:16

0:00:37

0:00:37

0:11:47

0:11:47

0:00:35

0:00:35

0:09:45

0:09:45

0:12:01

0:12:01

0:00:14

0:00:14

0:00:24

0:00:24

0:00:06

0:00:06

0:00:23

0:00:23