filmov

tv

How 1 Man Took on Prusa Research And... Won ? XL Enclosure Comparison

Показать описание

Could it be that a solo designer out classed an entire department at Prusa Research? Perhaps. In this video I compare Josef's Original Prusa enclosure for the Prusa XL to the aftermarket Sumo enclosure, designed by Joseph Willis from 3D Sourcerer. I compare these two alternatives on the basis of 5 criteria: ease of assembly, aesthetics, performance, value added features and overall value for money. To answer the question of which enclosure is easier to assemble I challenged two 3D printing enthusiasts to a race to see who could assemble their enclosure quicker. The results surprised me.

00:00 Introduction

00:53 The Criteria

01:30 Assembly Challenge

07:39 Ease of Assembly

08:48 Aesthetics

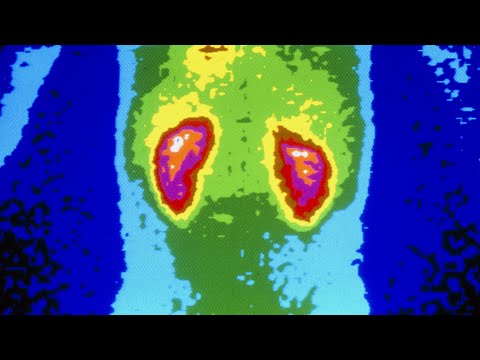

09:36 Performance

12:11 Value Added Features

14:13 Value For Money

14:52 The Results

15:12 Discussion

00:00 Introduction

00:53 The Criteria

01:30 Assembly Challenge

07:39 Ease of Assembly

08:48 Aesthetics

09:36 Performance

12:11 Value Added Features

14:13 Value For Money

14:52 The Results

15:12 Discussion

How 1 Man Took on Prusa Research And... Won ? XL Enclosure Comparison

How One Man Took On The Russian Woodpecker

A Man Took 90 Goat Dewormer Tablets And It Ruined His Life

When 1 Man Held Off 6 Tanks

What If There Was 1 Man And 7000000000 Women?

The Man Who Took LSD and Changed The World

We took the mask off the creepy man😱 #shorts

It took me 19 years to realize this 😱🤯😰 #disney #theory #moana #moana2 #vaiana #vaiana2

The old man took in an alien in his home 😲 | Jules | #movie

WE'RE BACK! FULHAM 0-1 MAN UNITED GOLDBRIDGE MATCH REACTION

The LEGENDARY ending to Game 1 of the World Series 🔥 #mlb #baseball #dodgers #freddiefreeman

The Gurkha who took on 200 Soldiers with only One Hand

How 1 Man’s Brain Injury Turned Him Into A Math Savant

When 1 Pilot Fought 64 Japanese Planes

A Man Took 1176 Ibuprofen Tablets In A Month. This Is What Happened To His Kidneys.

💀 It Took Me 9 Years To Realize This😰🤯😱

When 1 Tank Defeated 22 German Tanks

This happened when a man took 10000IU Vitamin D for years

This kind man took in a orphaned highland calf

Most Feared Soldier - The One-Man Army with 116 Kills

Man takes advantage of info before being arrested 😎 || White Collar S1E1 #shorts

Man Takes Off Shirt to Clean Barnacles Off Whale's Head from Small Boat #WhaleCare #BarnacleCle...

This Man Took a Poop So Big He Was Arrested

Bradley Martyn gets taken down by a man half his size 😤 #shorts #viral #reels #foryou #trending

Комментарии

0:16:49

0:16:49

0:23:56

0:23:56

0:12:00

0:12:00

0:05:18

0:05:18

0:05:18

0:05:18

0:33:40

0:33:40

0:00:19

0:00:19

0:00:29

0:00:29

0:00:58

0:00:58

0:33:01

0:33:01

0:00:52

0:00:52

0:04:17

0:04:17

0:12:03

0:12:03

0:10:34

0:10:34

0:13:13

0:13:13

0:01:00

0:01:00

0:06:25

0:06:25

0:00:59

0:00:59

0:01:00

0:01:00

0:11:59

0:11:59

0:00:42

0:00:42

0:00:06

0:00:06

0:00:40

0:00:40

0:00:22

0:00:22