filmov

tv

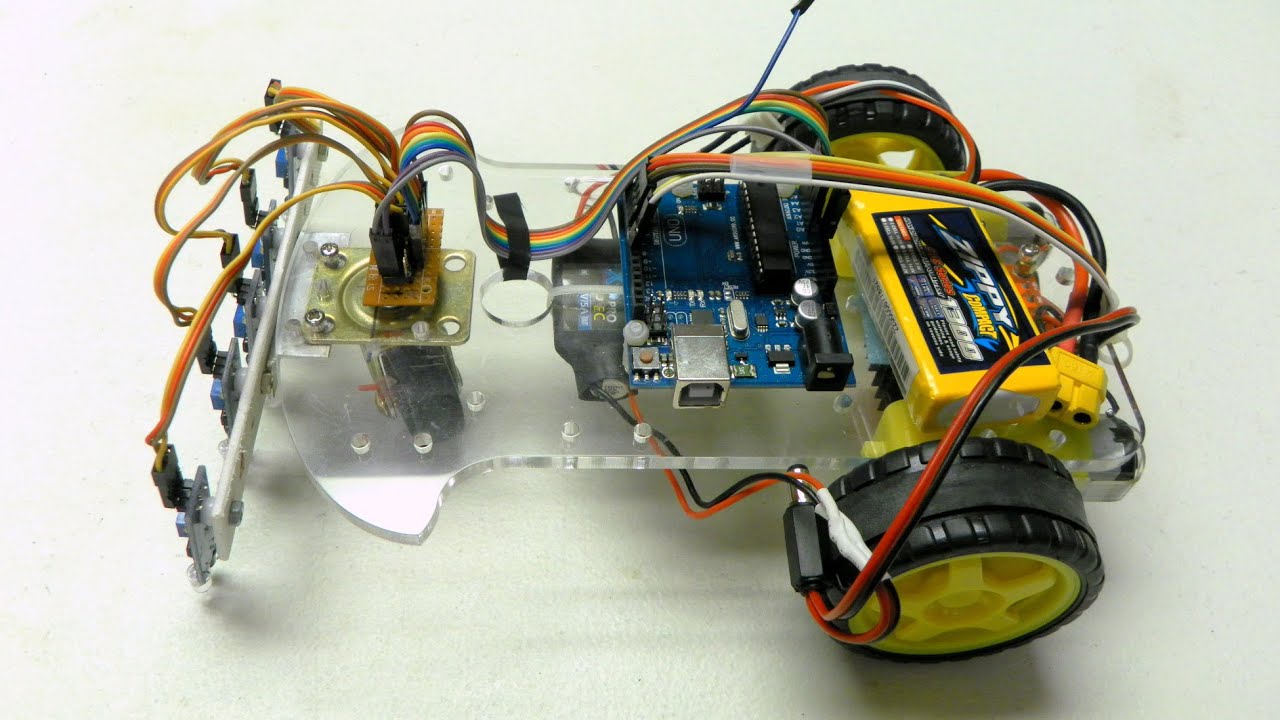

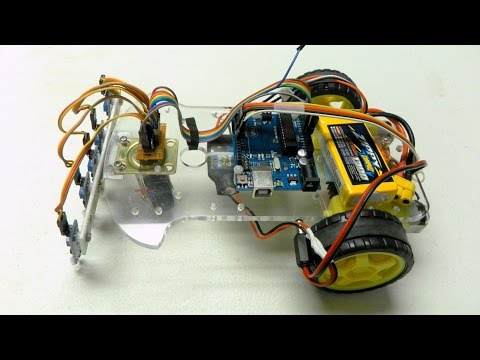

Arduino Five Sensor PID Line Following Robot

Показать описание

PLEASE READ THE VIDEO DESCRIPTION.

WEBSITE URL HAS BEEN TAKEN DOWN. ARDUINO SKETCH POSTED IN MY COMMENT.

Built the third version of a line following robot using five sensors and PID based code. This is the best line following robot so far as it a) travels the fastests and b) tracks the best even if the sensors go beyond the black line.

WEBSITE URL HAS BEEN TAKEN DOWN. ARDUINO SKETCH POSTED IN MY COMMENT.

Built the third version of a line following robot using five sensors and PID based code. This is the best line following robot so far as it a) travels the fastests and b) tracks the best even if the sensors go beyond the black line.

Arduino Five Sensor PID Line Following Robot

Arduino Uno | Arduino Line Follower Robot with 8 Line Sensors using Multiplexer and PID Controller

HBFS Line Follower - Next Generation of Robots

How to Make Arduino PID LINE FOLLOWER #linefollower #arduino #electronics

Arduino Line Follower. 5 Channel TCRT5000 IR Sensor. L298N, testing

Arduino Five sensors PID Line following Robot

[Arduino] P002 PID linefollower 5 sensors project

Line following robot || LFR using 5x IR Sensor Array,Arduino NANO,L298N driver.

PID Line Follower Tuning KP=0.028 KD=0.0

Line follower Robot using 5 Channel IR Sensor & Arduino

Arduino Uno PID Controlled Line Follower Robot by Torres et al. (2023)

How to code your Line follower robot with PID control and working code!

Arduino line follower with state machine and PID

Arduino Line Follower Robot Track C

robot race. line follower robot with arduino program

How to Make PID Line Follower Robot Using Arduino

Arduino Uno PID Controlled Line Follower Robot by Contrivida et al. (2023)

How to Write a Simple PID Line Follow Algorithm

How To Make A DIY LINE FOLLOWER using Arduino at Home

DIY Radar With Ultrasonic Sensor And Chat-GPT Generated Arduino Code | Coders Cafe

Beyond the Basics: Automatic Gatekeeper With IR Sensor And ChatGPT Generated Arduino Code

Arduino Line Follower PID Robot

Amazing arduino project | Check description to get free money.

Ultimate Line Following Robot with Arduino | Direct Port Manipulation | 5 IR Sensors #robotics #robo

Комментарии

0:03:53

0:03:53

0:17:55

0:17:55

0:00:22

0:00:22

0:00:29

0:00:29

0:00:18

0:00:18

0:00:48

0:00:48

![[Arduino] P002 PID](https://i.ytimg.com/vi/YJR3oLo029g/hqdefault.jpg) 0:01:04

0:01:04

0:00:40

0:00:40

0:00:21

0:00:21

0:05:28

0:05:28

0:00:53

0:00:53

0:06:54

0:06:54

0:00:53

0:00:53

0:00:17

0:00:17

0:00:23

0:00:23

0:06:50

0:06:50

0:01:47

0:01:47

0:26:14

0:26:14

0:03:58

0:03:58

0:00:19

0:00:19

0:00:10

0:00:10

0:00:15

0:00:15

0:00:16

0:00:16

0:00:14

0:00:14