filmov

tv

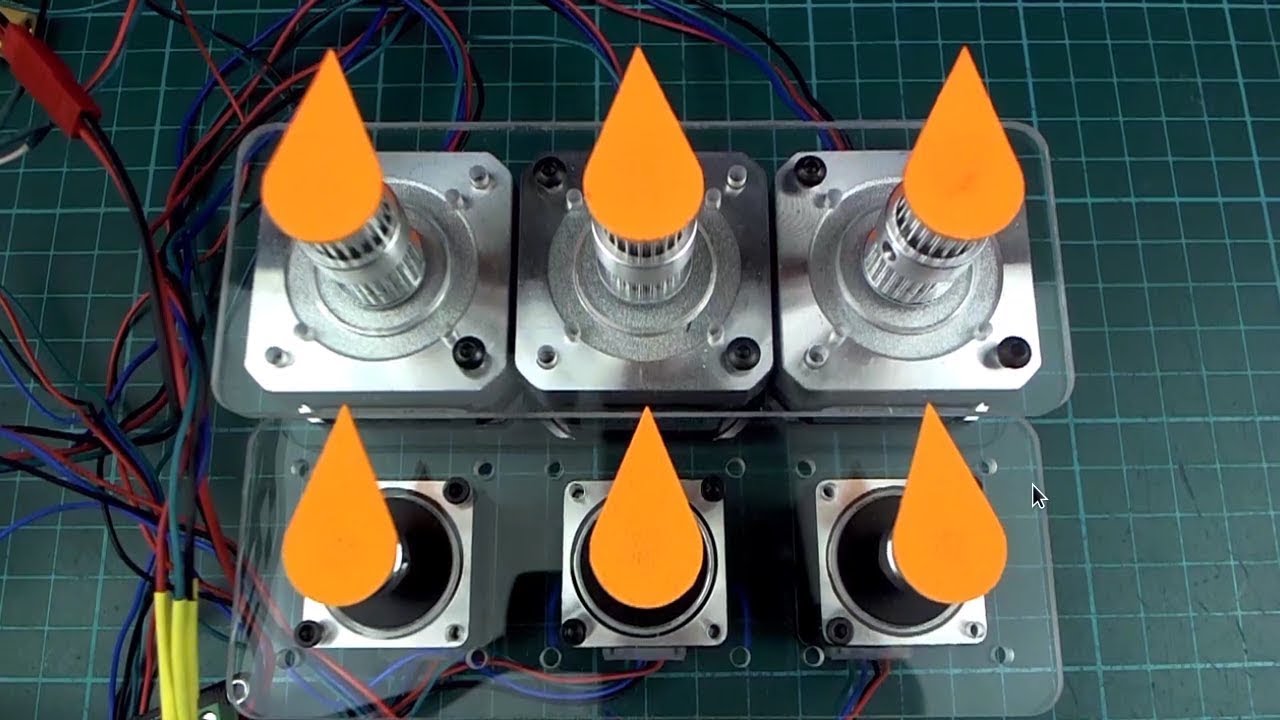

Coordinated stepper motor control (arduino)

Показать описание

Coordinated stepper motor control (arduino)

Stepper Motors and Arduino - The Ultimate Guide

Coordinated stepper motors / Arduino AccelStepper at Random movement

Arduino - Homing Stepper Motors using the AccelStepper Library - Tutorial

stepper motor speed controller reverse or forward controller

High speed stepper motor smooth acceleration and speed change with Teensy 3.5 and TeensyStep

Arduino stepper motor control #stepper_motor #steppers

Stepper Motor forward motion 1/4 step with Arduino Uno

Stepper motor & Arduino Motor Shield

Arduino dual steppers with switch

Arduino with AccelStepper library and TB6600 stepper motor controller

Stepper Motor Control system || 🤖 #Shorts

Stepper Motor Control Using Arduino

Dual Stepper Motors with Push Button Control

Fast robot arm with linear acceleration and circles #arduino #robotarm #steppermotor

xiao-stepper

Homing with the AccelStepper library and a limit switch

How to interface Stepper motor with arduino uno

Nema23 Stepper Motor and TB6600 Arduino (Quick tutorial for beginners)

VB.NET with Arduino controlling Stepper Motor through RFID Reader

Use Arduino to Control a Large Stepper Motor! Part 2

Stepper Motor Door Opening Project Arduino Nano #shorts

Specifying points on X-Y coordinate with stepper motors

Stepper Motors with Arduino - Controlling Bipolar & Unipolar stepper motors

Комментарии

0:47:11

0:47:11

0:29:57

0:29:57

0:01:15

0:01:15

0:07:23

0:07:23

0:00:21

0:00:21

0:00:26

0:00:26

0:00:12

0:00:12

0:00:30

0:00:30

0:00:17

0:00:17

0:00:38

0:00:38

0:24:48

0:24:48

0:00:16

0:00:16

0:00:28

0:00:28

0:00:14

0:00:14

0:00:14

0:00:14

0:00:14

0:00:14

0:17:09

0:17:09

0:00:09

0:00:09

0:03:34

0:03:34

0:00:16

0:00:16

0:15:47

0:15:47

0:00:18

0:00:18

0:00:23

0:00:23

0:50:22

0:50:22