filmov

tv

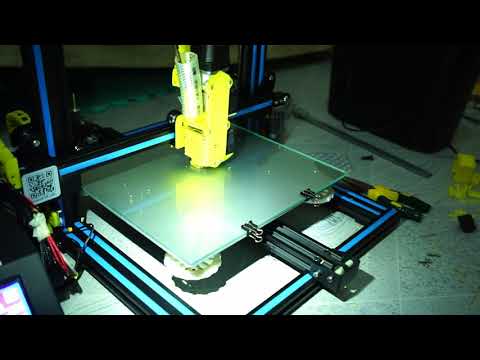

Granule printer with extruder V5 2: Test print 3DBenchy

Показать описание

More about Extruder V5.2 on HomoFaciens:

Subscribe to my channel to get the latest on Physical Computing:

You would like to spend me a can of peanuts or a bar of chocolate or both or even more as a very special thank you for my work on this and other open source projects?

Donate on HomoFaciens:

Become a Patreon on:

Many, many thanks for any Obol!

More videos of the series:

Plastic recycling:

Table Of Contents:

00:00 Introduction

00:53 Extruder V5.2

02:28 3DBenchy: First Layer

05:20 3DBenchy: Infill

06:20 3DBenchy: Deck

07:26 3DBenchy: Lower structure

08:27 3DBenchy: Anchor gap

09:27 3DBenchy: Bow tip

10:24 3DBenchy: Cabin

11:22 3DBenchy: Roof

12:24 3DBenchy: Chimney

14:05 Conclusion

Subscribe to my channel to get the latest on Physical Computing:

You would like to spend me a can of peanuts or a bar of chocolate or both or even more as a very special thank you for my work on this and other open source projects?

Donate on HomoFaciens:

Become a Patreon on:

Many, many thanks for any Obol!

More videos of the series:

Plastic recycling:

Table Of Contents:

00:00 Introduction

00:53 Extruder V5.2

02:28 3DBenchy: First Layer

05:20 3DBenchy: Infill

06:20 3DBenchy: Deck

07:26 3DBenchy: Lower structure

08:27 3DBenchy: Anchor gap

09:27 3DBenchy: Bow tip

10:24 3DBenchy: Cabin

11:22 3DBenchy: Roof

12:24 3DBenchy: Chimney

14:05 Conclusion

Granule printer with extruder V5 2: Test print 3DBenchy

Granule printer V5.3,, track link, full print

Conversion of a Prusa MK4 to granule extruder V5 0

Pellet Exstruder, First Test Print

🇺🇸 🇬🇧 Direct Granule Printer Part 4: Printing recycled PLA

Direct Granule Printer Prusa MK4: Part 6

Direkt Granulat Extruder V3: Entwicklungsgeschichte

DCycle Filament Extruder Testing

Don’t buy 3D filament DIY with you lab extruder

3D printing with granules and a Prusa MK4, Part 2

Fresh from the lab of the Nutty Professor (3D Printing)

Direct Granule Extruder V4.1: Auger screws

RepRapable Recyclebot

3D printing with a Prusa MK4 and PLA powder, part 3

3rd try extrusion hdpe

Pellet Extruder (v4) Mahor.xyz

abs pla mini lab 3d filament extruder extrusion machine line

Filastruder

Extruder ABS

DIY 6 Kg Filament Extruder Clear TPU Shore 75 A And It Goes Well

Homemade Printrbot Flexible Filament Direct Drive Extruder DIY 3D Printer Machine Aluminium Frame a

MKMakerONE 03 (3D + Print + MKMO) build your own 3D Printer with 2020 extrusion designed in OnShape

Desktop Filament Extruder Pt 1 #filamentextruder #3dprinting #3dprinter

DIY FIlament Extruder: Part 7 - Improved puller and mixture of different granules.

Комментарии

0:16:05

0:16:05

0:14:34

0:14:34

0:16:19

0:16:19

0:03:30

0:03:30

0:07:22

0:07:22

0:08:36

0:08:36

0:11:47

0:11:47

0:00:29

0:00:29

0:00:12

0:00:12

0:10:02

0:10:02

0:01:27

0:01:27

0:11:20

0:11:20

0:00:31

0:00:31

0:11:04

0:11:04

0:00:58

0:00:58

0:00:43

0:00:43

0:00:31

0:00:31

0:01:04

0:01:04

0:00:09

0:00:09

0:01:01

0:01:01

0:03:49

0:03:49

0:04:54

0:04:54

0:21:46

0:21:46

0:08:35

0:08:35