filmov

tv

Measuring Total External Static Pressure

Показать описание

Video demonstration by Jim Bergmann of TruTech Tools of how to make a total external static pressure readings on a furnace and how to calculate what the external static pressure will be before replacing a furnace or air conditioner.

How Check Total External Static Pressure On An Air Handler Or Furnace

How to Measure Total External Static Pressure (TESP)

How to measure External Static Pressure with Tony Gonzalez of Fieldpiece

Measuring Total External Static Pressure

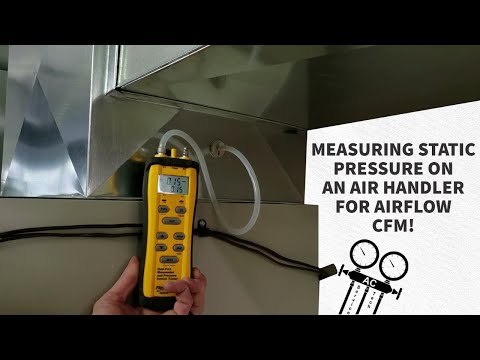

Measuring Static Pressure on an Air Handler for Airflow CFM!

Static Pressure Testing and Mapping Demonstration

How to Measure Total Static Pressure w/ Testo 510i

How to Measure the Total External Static Pressure on an HVAC System.

Is there really a genetic lock in humans? What would happen if it was unlocked? - part 3 - FULL

Static Pressure and Manometer Basics

Tech Tips: Static Pressure Testing

Static Pressure Testing for Home HVAC: What, Why, and How in 2 Minutes

Manual D - Maximum External Static Pressure

HVAC MYSTERY: Testing Air Conditioning Airflow & External Static Pressure

Technical Tuesdays Ep.6 - Total External Static Pressure Part I

How to use Static Pressure to Measure and Set Air Flow

The Four Test Locations for HVAC Static Pressure

HVAC Air Flow_Step-by-step_TESP

External Static Pressure (ESP)

Easily understand about the Static pressure and External Static pressure

Static Pressure Explained

Practical Training on Manometers

Measuring External Static Pressure

Total External Static Pressure Test

Комментарии

0:04:28

0:04:28

0:07:22

0:07:22

0:04:27

0:04:27

0:23:56

0:23:56

0:08:08

0:08:08

0:11:05

0:11:05

0:01:52

0:01:52

0:05:35

0:05:35

12:53:47

12:53:47

0:32:33

0:32:33

0:08:19

0:08:19

0:01:52

0:01:52

0:05:55

0:05:55

0:01:01

0:01:01

0:01:49

0:01:49

1:34:29

1:34:29

0:02:06

0:02:06

0:13:01

0:13:01

0:02:58

0:02:58

0:06:04

0:06:04

0:03:19

0:03:19

0:18:58

0:18:58

0:08:38

0:08:38

0:03:16

0:03:16