filmov

tv

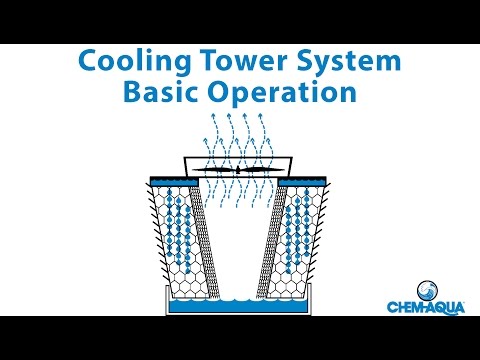

Water treatment in Cooling Towers with HydroFLOW®

Показать описание

Cooling Tower Case Study Results with HydroFLOW®:

Limescale and Corrosion prevented

Biocide Reduced by 80%

Bacteria down from 100,000 CFU to 1,000 CFU

Blowdown reduced by 50%

HydroFLOW® addresses the three main problems of Cooling Tower Operation: Limescale, Biofouling, Excessive Blowdown.

In this video we showcase a Cooling Tower in Hawaii,

2 x 300-ton tower cells with 14” pipelines. The objective was to keep scaling and biofouling under control and reduce chemicals.

Results with HydroFLOW®:

Limescale and Corrosion prevented

Biocide Reduced by 80%

Bacteria down from 100,000 CFU to 1,000 CFU

Blowdown reduced by 50%

Limescale:

HydroFLOW® protects heat exchangers and cooling tower surfaces from limescale preserving efficiency and reducing maintenance costs

Bio-fouling and Excessive Blowdown:

Water quality is improved with HydroFLOW® due to flocculation and bio-fouling treatment which reduces blowdown, saving water and sewage costs

Installation:

HydroFLOW® is easy to retrofit, without cutting existing pipes

HydroFLOW® transmits a signal into the water so limescale forms as a powder which is washed away with the flow. Dirt particles in the water get charged and flocculate together in larger clumps so they are more easily removed by the filter

Limescale and Corrosion prevented

Biocide Reduced by 80%

Bacteria down from 100,000 CFU to 1,000 CFU

Blowdown reduced by 50%

HydroFLOW® addresses the three main problems of Cooling Tower Operation: Limescale, Biofouling, Excessive Blowdown.

In this video we showcase a Cooling Tower in Hawaii,

2 x 300-ton tower cells with 14” pipelines. The objective was to keep scaling and biofouling under control and reduce chemicals.

Results with HydroFLOW®:

Limescale and Corrosion prevented

Biocide Reduced by 80%

Bacteria down from 100,000 CFU to 1,000 CFU

Blowdown reduced by 50%

Limescale:

HydroFLOW® protects heat exchangers and cooling tower surfaces from limescale preserving efficiency and reducing maintenance costs

Bio-fouling and Excessive Blowdown:

Water quality is improved with HydroFLOW® due to flocculation and bio-fouling treatment which reduces blowdown, saving water and sewage costs

Installation:

HydroFLOW® is easy to retrofit, without cutting existing pipes

HydroFLOW® transmits a signal into the water so limescale forms as a powder which is washed away with the flow. Dirt particles in the water get charged and flocculate together in larger clumps so they are more easily removed by the filter

0:03:36

0:03:36

0:13:09

0:13:09

0:01:51

0:01:51

0:02:53

0:02:53

0:02:09

0:02:09

0:03:17

0:03:17

0:51:50

0:51:50

0:03:12

0:03:12

0:03:17

0:03:17

0:01:20

0:01:20

0:34:57

0:34:57

0:01:00

0:01:00

0:03:31

0:03:31

0:01:03

0:01:03

0:03:14

0:03:14

0:18:58

0:18:58

0:02:22

0:02:22

0:05:09

0:05:09

0:02:03

0:02:03

0:03:25

0:03:25

0:44:50

0:44:50

0:01:09

0:01:09

0:01:47

0:01:47

0:01:50

0:01:50