filmov

tv

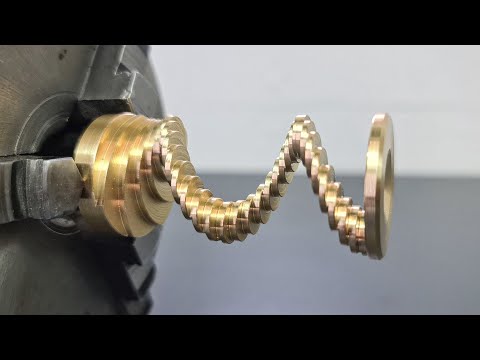

INCREDIBLE Techniques Behind Machining Long Spline Shafts

Показать описание

This is game-changing technology that made cnc machining this part on the Tornos GT32 Swiss lathe so much easier. The tools used in the machine made cutting through steel a breeze, a must have for any job shop.

00:00 Machining

00:22 Introduction

00:44 kennametal's Cermet Tool

01:31 Tool by Horn

02:01 Programming in Solidcam

04:32 How to eject your finished parts

06:12 Outro

#Machining #Machinist #Engineering

00:00 Machining

00:22 Introduction

00:44 kennametal's Cermet Tool

01:31 Tool by Horn

02:01 Programming in Solidcam

04:32 How to eject your finished parts

06:12 Outro

#Machining #Machinist #Engineering

This Modern Bridge Construction Method is Very INCREDIBLE. Amazing Construction Equipment Machine ▶2...

Powerful Roughing with Incredible Indexable Cutters | CNC Mill Tooling + Machining

Ingeniously Rebuild Broken Clutch Flywheel With Incredible Technique

How To Straighten the Bent Hydraulic Cylinder Rod with Incredible Technique

Incredible Woodworking Techniques and Wood Carving Machines

Behind the Build: Incredible Science Machine GAME ON!

Amazing Technique With a thread drill on a lathe machine, it is difficult to make worms

Incredible Hybrid Technology | 5 Axis CNC Machining | Titanium Additive Manufacturing | DMG MORI

Process of Making Ship's Propellor with Amazing Technique

This welder is truly amazing.

How To Rebuild a Broken Flywheel With Amazing Technique

This Farmer Invented a Homemade Farming Machine - Incredible Ingenious Agriculture Inventions

Incredible 5 Axis Machining Techniques Revealed | DN Solutions DVF 5000

Making a Crazy Part on the Lathe - Manual Machining

Amazing Machining Process of Industrial Double Helical Pinion Shaft with 100yrs old Technology

Amazing Technology CNC Cutting Machine Tools, CNC Lathe Turning Machine Working

Manufacturing process of Square Pipes with Amazing old Technology

Fastest CNC Lathe Turning Machine Working, Amazing CNC Milling Machine Modern Technology

Watch Pro Mechanic’s Amazing Technique to Repair an Excavator Shaft #restoration #excavator

Modern CNC Lathe Turning Machine Working, Amazing CNC Machining Machines

'Zero Tolerance Machining' with the Wire EDM, Making a Puzzle Cube - Part 2 | US Digital

Incredible Machining: Parts Made In Seconds Using 8 Spindles

Wow amazing Pakistani new technique work

#automaticmachine #working #technology #machine #amazing #work #factory #shorts #manufacturing

Комментарии

0:11:53

0:11:53

0:05:50

0:05:50

0:01:00

0:01:00

0:01:00

0:01:00

0:32:18

0:32:18

0:12:51

0:12:51

0:14:06

0:14:06

0:05:59

0:05:59

0:01:00

0:01:00

0:01:00

0:01:00

0:01:00

0:01:00

0:08:05

0:08:05

0:06:24

0:06:24

0:04:15

0:04:15

0:01:00

0:01:00

0:10:36

0:10:36

0:01:00

0:01:00

0:14:06

0:14:06

0:01:00

0:01:00

0:11:31

0:11:31

0:02:55

0:02:55

0:13:49

0:13:49

0:01:00

0:01:00

0:00:11

0:00:11