filmov

tv

Robotic Arm Motor Selection

Показать описание

In this video, I explore the different types of motors that could be used in the robotic arm project, and explain the advantages and disadvantages of each one. Below are some great videos that I've watched in the past on some topics covered in this video

Learn how a DC motor works:

Learn how a servo motor works:

Learn how a stepper motor works:

Learn to use A4988 driver:

Learn how a DC motor works:

Learn how a servo motor works:

Learn how a stepper motor works:

Learn to use A4988 driver:

Robotic Arm Motor Selection

⚙️Learn engineering CALCULATING “motor size and torque” using math to SAVE TIME

Servo vs Stepper Motors

6-Axis Servo Robot Arm

How to Determine the Motor Size for Your Project?

Unlocking 11 Nm Torque: The Ultimate Robot Actuator

What The Differences Between Stepper Motors And Servo Motors

Robotic Arm assembly. 3D printed Robot arm. #engineering #actuators #robot #roboticarm #robotics

Different servo motors (from 35g to 3kg.m)

4 axis stepper motor robot

Robot Actuator (Brushless Motor Robotic Joint)

RoboBench: Choosing Motors & Servos

Quick Guide to Servos

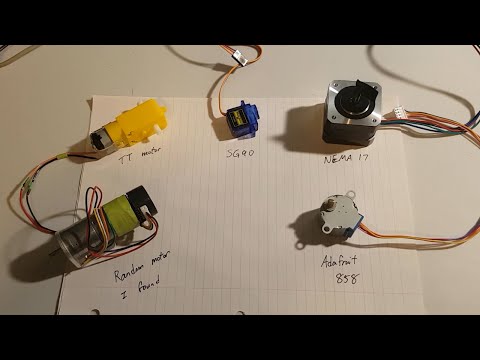

What are the Different Types of Motors used in DIY Robotics? Robotics Tutorial for Beginners

OYOSTEPPER Nema 23 stepper motor for 5 Axis Robot Arm #cnc #automation #factory #industry #robot

our servo motor application in robot arm

How to Select a Frameless Motor for Your Collaborative Robot - Two Minutes of Motion

How to Calculate Motor Torque

DYNAMIXEL Selection Guide (2022)

Selecting a Frameless Motor for a Robotic Joint | Kollmorgen | 2 Min of Motion

Robotic arm using BLDC MOTORS #bldcmotor #arduino #drones

high torque dc worm gear 5840-31zy for robot arm etc..

Lucid ONE: AI Planning 7-DOF Robotic Arm Review

Build a REAL Robot Episode 3 - Selecting Motors

Комментарии

0:14:18

0:14:18

0:14:02

0:14:02

0:02:32

0:02:32

0:00:46

0:00:46

0:15:08

0:15:08

0:01:15

0:01:15

0:00:38

0:00:38

0:01:00

0:01:00

0:10:55

0:10:55

0:00:21

0:00:21

0:08:18

0:08:18

0:05:50

0:05:50

0:04:15

0:04:15

0:10:03

0:10:03

0:00:09

0:00:09

0:00:15

0:00:15

0:02:14

0:02:14

0:02:26

0:02:26

0:12:00

0:12:00

0:03:16

0:03:16

0:00:16

0:00:16

0:00:58

0:00:58

0:02:11

0:02:11

0:24:09

0:24:09