filmov

tv

We're Installing Solar! How It's Going So Far...

Показать описание

#AnkerSOLIX #LIVEINPOWER #AnkerSOLIXF3800

I'm in the process of installing solar panels that will feed in to my Anker SOLIX F3800 system. I'll have a full video coming soon on this but I wanted to give you guys a behind the scenes look on the progress so far. Let me know what you think!

Thanks for watching!

Amazon and Anker affiliate links above.

Very Impressive #Solar Installation on a Roof💪 - Subscribe for more! ☀️

SOLAR POWER: The Ultimate Beginner's Guide / How To

Do It Yourself Solar Power? - Easy DIY Solar Panel Installation!

Solar Panel Installation

Should You Go Solar? A Super Helpful Beginner's Guide to Home Solar Power

Solar Stack - The Fastest Way to Install Solar

True Cost of Solar Panels | DON'T WASTE YOUR MONEY

Installing SOLAR was a TERRIBLE idea! 💨

Build a DIY Solar Generator in 30 Minutes

Installing Solar Panels on our Workshop Roof. Snap-N-Rack Roof Mount with 7.36 Kilowatts of Solar

Beginner And Budget Friendly DIY Solar Power System! Anyone can build this!

How to Install Solar Panels - a COMPLETE DIY Guide

10 Things You Need To Know Before Getting Solar Panels Installed in 2024

Solar Power for dummies, This system is easy!

Beginner Friendly DIY Off-Grid ROYPOW Solar Energy Storage System - Step by Step

How we install a solar PV roof hook ☀️#renewableenergy #renewables #solarpv #solar #energy

can we make more Efficient solar panels ? Elon Musk

Installing a Solar PV System in Ireland. A Look at the Kit and What to Consider. What's Involve...

SolarEdge Power Optimizer Connection

How Much Does Solar Panel Installation Cost, and Is It Worth It? | Unique Homes | OG

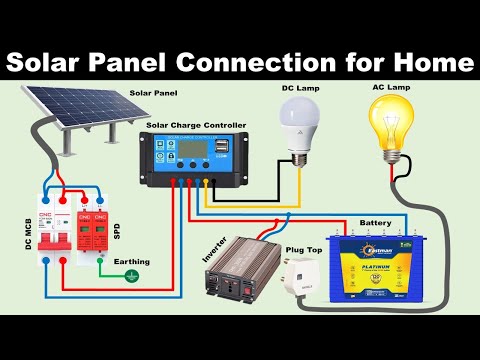

Complete Solar Panel Connection with Solar Charge Controller and Inverter @TheElectricalGuy

DIY Solar Setup: Easy to Follow Step-by-Step Instructions

How we do RV Solar Panels Installations

RV Solar 101 : Everything a Beginner Needs to Know !

Комментарии

0:00:16

0:00:16

0:11:25

0:11:25

0:16:24

0:16:24

0:00:17

0:00:17

0:11:35

0:11:35

0:00:24

0:00:24

0:02:05

0:02:05

0:23:50

0:23:50

0:00:27

0:00:27

0:22:53

0:22:53

0:08:00

0:08:00

0:23:57

0:23:57

0:19:21

0:19:21

0:11:40

0:11:40

0:30:56

0:30:56

0:01:00

0:01:00

0:00:34

0:00:34

0:31:51

0:31:51

0:00:45

0:00:45

0:09:37

0:09:37

0:06:30

0:06:30

0:13:42

0:13:42

0:00:33

0:00:33

0:22:41

0:22:41