filmov

tv

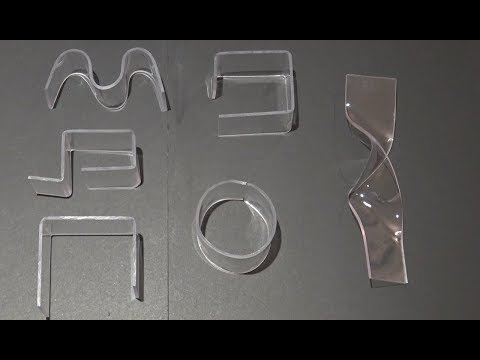

Form Bending Sheet Acrylic for a Curved Display Case

Показать описание

Heat forming acrylic into a circular arc shape. This video includes how to make the curved arc form from wood, and heating the acrylic in my kitchen oven, which is NOT a safe way to do it.

Display case build video...

Links referenced in this video. *affiliate

Intro - 0:00

Making form - 0:34

Cutting acrylic - 3:31

Heating acrylic - 4:29

Out of oven and forming - 6:45

*affiliate - As an Amazon Associate I earn from qualifying purchases, at no additional cost to you.

Display case build video...

Links referenced in this video. *affiliate

Intro - 0:00

Making form - 0:34

Cutting acrylic - 3:31

Heating acrylic - 4:29

Out of oven and forming - 6:45

*affiliate - As an Amazon Associate I earn from qualifying purchases, at no additional cost to you.

Form Bending Sheet Acrylic for a Curved Display Case

Form Bending Acrylic and PVC Plastic

Bending and forming PLEXIGLAS®: Perfect thermoforming in just a few steps

How to easily bend plexiglass, lexan and acrylic sheets

How to Bend Acrylic and Make Amazing Shapes

Acrylic Bending using a Wooden Form

Custom acrylic plexiglass sheet vacuum forming service

Acrylic Bending (for Dummies)

Ammnra Quick Tip: Heat Bending Sheet Acrylic

Adam Savage's Favorite Tools: Plastic Forming Strip Heater!

Bend Acrylic with Propane Forge Burner?

How to make acrylic dome, Custom acrylic domes, acrylic domes manufacturer

Melicsigns - Acrylic Bending Tool

Thermoformed 1 Inch Thick Acrylic Sheet

How to Bend Acrylic and Plexiglass - 3 Easy Ways

How to heat bend acrylic sheet ?

Bending Acrylic Sheets in Z and U forms with the BERMAQ® DA Machine.

Acrylic Bending

Acrylic Drape Forming. Moulding Perspex to any shapes.

Acrylic vs Polycarbonate (aka Lexan vs Plexiglas)

10 tips & tricks PLEXIGLASS working HOMEMADE

Manual Acrylic Bending Machine for PP, Plexiglass, Plastic sheet, organic glass

Economic Acrylic Bender for bending acrylic, PP, Plexiglass, Plastic sheet, organic glass

Bending Acrylic #shorts

Комментарии

0:08:05

0:08:05

0:01:00

0:01:00

0:03:58

0:03:58

0:06:11

0:06:11

0:06:36

0:06:36

0:04:40

0:04:40

0:00:26

0:00:26

0:10:13

0:10:13

0:04:29

0:04:29

0:09:52

0:09:52

0:08:25

0:08:25

0:00:33

0:00:33

0:00:33

0:00:33

0:00:49

0:00:49

0:05:10

0:05:10

0:00:37

0:00:37

0:01:37

0:01:37

0:00:20

0:00:20

0:01:21

0:01:21

0:10:03

0:10:03

0:12:36

0:12:36

0:02:31

0:02:31

0:00:56

0:00:56

0:00:39

0:00:39