filmov

tv

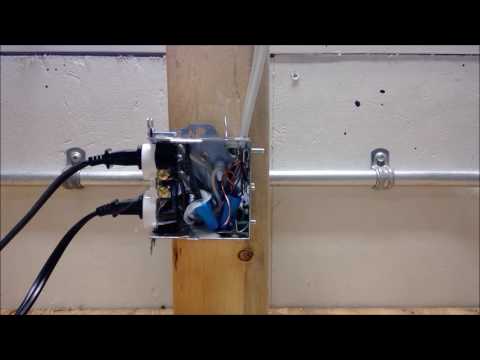

LOOSE WIRES CAUSE FIRES 🔥 - A TORQUE SCREWDRIVER WON'T HELP!

Показать описание

A torque screwdriver doesn't replace the skill and competence of a good electrician. We explore the common mistakes some installers make which won't be detected by using an electricians torque screwdriver.

The mistakes shown in this video can lead to electrical fires, damaged consumer units and expensive repairs. All are easily avoided with care, attention and skill.

✅ More from the eFIXX Talk the Torque series:

Electrical safety first report on consumer unit meter tails

======================

🕐 TIME STAMPS 🕕

======================

00:00 Poor terminations

00:36 Give it a wiggle

01:15 Adding a new consumer unit

02:08 How do you prepare your meter tails

02:49 PVC is a poor conductor

03:11 Poor termination

03:51 To the side of the screw

04:43 Missing the bus bar

05:54 Damaged conductors

06:38 Missing conductor strands

===========================================

FREE Approved CPD training module in association with Wiha

===========================================

AD

Torque screwdrivers we use from Wiha

===========================================

================================

========================================

THIS CHANNEL IS POWERED BY YOU

We create fresh electrical content every day. What we produce is influenced by the thousands of subscribers who send us messages, leave comments and share our videos. We are always looking for new ways to collaborate and celebrate best practices.

========================================

eFIXX - EDDY CURRENT MERCH

========================================

🔴 eFIXX LIVE Join us for our youtube live stream twice a month - features product sneak peeks, challenges, giveaways and live electrical banter.

================================

================================

================================

================================

FOLLOW US on your favourite social networks for behind the scenes action, breaking news and competitions.

==================================

❌ This content on this channel is for electrical professionals.❌ ==================================

📹 Presented by

Gary Hayers - Editor eFIXX

Gordon Routledge CEng MIET - Technology Editor eFIXX ===================================

#efixx #electricians #consumerunits

The mistakes shown in this video can lead to electrical fires, damaged consumer units and expensive repairs. All are easily avoided with care, attention and skill.

✅ More from the eFIXX Talk the Torque series:

Electrical safety first report on consumer unit meter tails

======================

🕐 TIME STAMPS 🕕

======================

00:00 Poor terminations

00:36 Give it a wiggle

01:15 Adding a new consumer unit

02:08 How do you prepare your meter tails

02:49 PVC is a poor conductor

03:11 Poor termination

03:51 To the side of the screw

04:43 Missing the bus bar

05:54 Damaged conductors

06:38 Missing conductor strands

===========================================

FREE Approved CPD training module in association with Wiha

===========================================

AD

Torque screwdrivers we use from Wiha

===========================================

================================

========================================

THIS CHANNEL IS POWERED BY YOU

We create fresh electrical content every day. What we produce is influenced by the thousands of subscribers who send us messages, leave comments and share our videos. We are always looking for new ways to collaborate and celebrate best practices.

========================================

eFIXX - EDDY CURRENT MERCH

========================================

🔴 eFIXX LIVE Join us for our youtube live stream twice a month - features product sneak peeks, challenges, giveaways and live electrical banter.

================================

================================

================================

================================

FOLLOW US on your favourite social networks for behind the scenes action, breaking news and competitions.

==================================

❌ This content on this channel is for electrical professionals.❌ ==================================

📹 Presented by

Gary Hayers - Editor eFIXX

Gordon Routledge CEng MIET - Technology Editor eFIXX ===================================

#efixx #electricians #consumerunits

Комментарии

0:02:55

0:02:55

0:00:15

0:00:15

0:00:11

0:00:11

0:00:26

0:00:26

0:02:30

0:02:30

0:00:26

0:00:26

0:07:25

0:07:25

0:04:59

0:04:59

0:00:59

0:00:59

0:00:15

0:00:15

0:00:41

0:00:41

0:03:00

0:03:00

0:00:27

0:00:27

0:04:21

0:04:21

0:01:01

0:01:01

0:02:46

0:02:46

0:00:30

0:00:30

0:00:16

0:00:16

0:00:32

0:00:32

0:01:30

0:01:30

0:00:12

0:00:12

0:00:09

0:00:09

0:00:40

0:00:40

0:03:33

0:03:33