filmov

tv

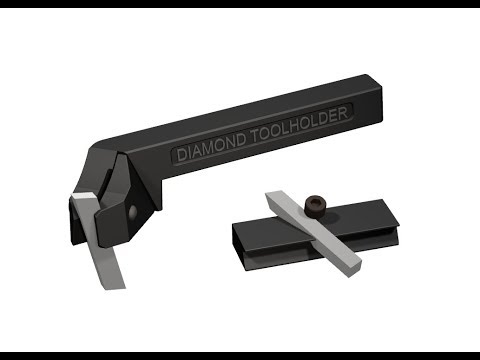

WHAT Are Tangential Lathe Tools?

Показать описание

G'day everyone,

I have made lots of lathe tools over the past few years, however one tool that I have not used is a tangential tool or a diamond lathe tool. These lathe tools are designed to use the end of a HSS blank as the cutting edge. The cutter is held almost vertically, but is tilted back at a slight angle to create the necessary relief. In doing so you only have to grind one face of the HSS lathe tool.

In this video I will be making my own lathe tool holder and grinding jig in order to be able to use the tangential tooling.

I hope you enjoy the video

Tangential lathe tooling

Tangential Tool Holder

Diamond Tool Holder

#machining #DIY #minilathe

Timestamps

0:00 - Intro

1:02 - Tool Holder - No Clearance

2:36 - Filing In Clearance By Hand

3:35 - Making A Grinding Jig In The Mill

4:56 - Testing The Grind

5:11 - Machining A Tool Holder In the Mill

6:37 - Testing The New Tool Holder

7:29 - Machining The Final Tool Holder

8:47 - Modifying The Clamping System

9:31 - Conclusion

Mini Lathe - Sieg c3 7x14 Metal Mini Lathe

Milling Machine - Sieg X2.7l

I have made lots of lathe tools over the past few years, however one tool that I have not used is a tangential tool or a diamond lathe tool. These lathe tools are designed to use the end of a HSS blank as the cutting edge. The cutter is held almost vertically, but is tilted back at a slight angle to create the necessary relief. In doing so you only have to grind one face of the HSS lathe tool.

In this video I will be making my own lathe tool holder and grinding jig in order to be able to use the tangential tooling.

I hope you enjoy the video

Tangential lathe tooling

Tangential Tool Holder

Diamond Tool Holder

#machining #DIY #minilathe

Timestamps

0:00 - Intro

1:02 - Tool Holder - No Clearance

2:36 - Filing In Clearance By Hand

3:35 - Making A Grinding Jig In The Mill

4:56 - Testing The Grind

5:11 - Machining A Tool Holder In the Mill

6:37 - Testing The New Tool Holder

7:29 - Machining The Final Tool Holder

8:47 - Modifying The Clamping System

9:31 - Conclusion

Mini Lathe - Sieg c3 7x14 Metal Mini Lathe

Milling Machine - Sieg X2.7l

Комментарии

0:10:29

0:10:29

0:16:07

0:16:07

0:12:59

0:12:59

0:13:21

0:13:21

0:02:49

0:02:49

0:00:09

0:00:09

0:02:45

0:02:45

0:29:15

0:29:15

0:06:53

0:06:53

0:04:26

0:04:26

0:00:53

0:00:53

0:09:05

0:09:05

0:20:17

0:20:17

0:02:57

0:02:57

0:22:46

0:22:46

0:09:11

0:09:11

0:03:58

0:03:58

0:33:44

0:33:44

0:17:20

0:17:20

0:16:55

0:16:55

0:00:12

0:00:12

0:05:15

0:05:15

0:00:07

0:00:07

0:23:45

0:23:45