filmov

tv

MRP vs MRP II vs ERP - A Comparison of Planning Systems

Показать описание

#MRP #MRPII #ERP #planning

MRP (Material Requirements Planning), MRP II (Manufacturing Resource Planning), and ERP (Enterprise Resource Planning) are all systems used to manage the manufacturing process.

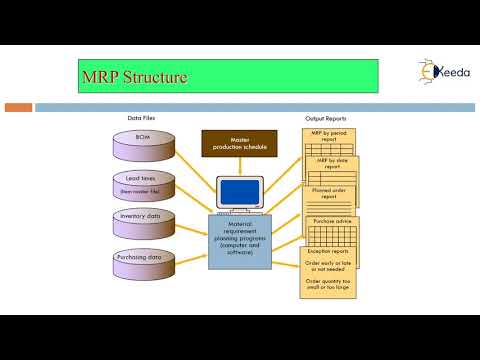

MRP is a computer-based system that calculates the materials and components needed to produce a finished product. It helps manufacturers to ensure that they have the necessary materials on hand to meet production demands and avoid stockouts.

MRP II extends the functionality of MRP by adding modules for other manufacturing functions such as capacity planning, shop floor control, and inventory management. It is a comprehensive system that provides manufacturers with real-time information about their production operations, enabling them to plan, monitor, and control the entire manufacturing process.

ERP is an even more extensive system that incorporates all the features of MRP and MRP II, as well as modules for other areas of the business, such as finance, human resources, supply chain management, and customer relationship management. ERP provides a complete view of an organization's operations, enabling managers to make better decisions, and streamline business processes.

In summary, while MRP focuses on calculating the materials and components required to produce a product, MRP II extends its functionality to include other manufacturing functions, and ERP extends further to include all aspects of the business, including finance, human resources, and customer relationship management. Each system provides increased functionality and a broader scope, enabling organizations to manage their operations more effectively and efficiently.

00:00 Intro

00:33 – Agenda

00:42 – Materials Requirements Planning (MRP)

01:43 – MRP – MRP II and ERP Systems Comparison

02:14 – Manufacturing Resource Planning (MRP II)

03:12 – Enterprise Resource Planning (ERP)

04:33 – Key Takeaways

Connect with me on Social Media!

MRP (Material Requirements Planning), MRP II (Manufacturing Resource Planning), and ERP (Enterprise Resource Planning) are all systems used to manage the manufacturing process.

MRP is a computer-based system that calculates the materials and components needed to produce a finished product. It helps manufacturers to ensure that they have the necessary materials on hand to meet production demands and avoid stockouts.

MRP II extends the functionality of MRP by adding modules for other manufacturing functions such as capacity planning, shop floor control, and inventory management. It is a comprehensive system that provides manufacturers with real-time information about their production operations, enabling them to plan, monitor, and control the entire manufacturing process.

ERP is an even more extensive system that incorporates all the features of MRP and MRP II, as well as modules for other areas of the business, such as finance, human resources, supply chain management, and customer relationship management. ERP provides a complete view of an organization's operations, enabling managers to make better decisions, and streamline business processes.

In summary, while MRP focuses on calculating the materials and components required to produce a product, MRP II extends its functionality to include other manufacturing functions, and ERP extends further to include all aspects of the business, including finance, human resources, and customer relationship management. Each system provides increased functionality and a broader scope, enabling organizations to manage their operations more effectively and efficiently.

00:00 Intro

00:33 – Agenda

00:42 – Materials Requirements Planning (MRP)

01:43 – MRP – MRP II and ERP Systems Comparison

02:14 – Manufacturing Resource Planning (MRP II)

03:12 – Enterprise Resource Planning (ERP)

04:33 – Key Takeaways

Connect with me on Social Media!

Комментарии

0:05:30

0:05:30

0:05:17

0:05:17

0:06:42

0:06:42

0:04:05

0:04:05

0:02:09

0:02:09

0:02:01

0:02:01

0:00:58

0:00:58

0:01:06

0:01:06

0:04:21

0:04:21

0:13:07

0:13:07

0:21:40

0:21:40

0:03:23

0:03:23

0:25:16

0:25:16

0:01:52

0:01:52

0:01:50

0:01:50

0:02:08

0:02:08

0:05:46

0:05:46

0:04:54

0:04:54

0:13:46

0:13:46

0:02:14

0:02:14

0:13:10

0:13:10

0:02:45

0:02:45

0:12:33

0:12:33

0:01:32

0:01:32