filmov

tv

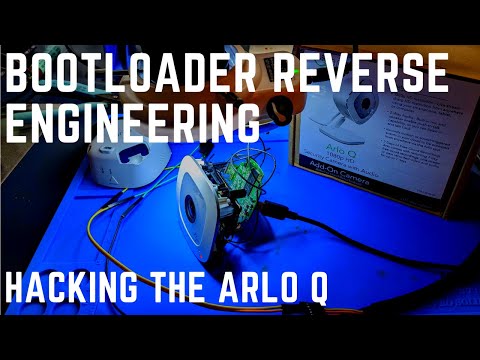

Hacking the Arlo Q Security Camera: Firmware Extraction

Показать описание

In this video, we continue hacking on the Arlo Q security camera. Today we extract firmware from the nand flash of the device and reattach the chip to leave the camera in working order. We use binwalk to extract file systems from the flash contents extracted from the device.

Louis Rossmann's Arlo video:

Arlo End of Life announcement:

IoT Hackers Hangout Community Discord Invite:

🛠️ Stuff I Use 🛠️

🪛 Tools:

🫠 Soldering & Hot Air Rework Tools:

🔬 Microscope Setup:

About Me:

My name is Matt Brown and I'm an Hardware Security Researcher and Bug Bounty Hunter. This channel is a place where I share my knowledge and experience finding vulnerabilities in IoT systems.

- Soli Deo Gloria

💻 Social:

#righttorepair #jailbreak #firmware #iot #hacking

Louis Rossmann's Arlo video:

Arlo End of Life announcement:

IoT Hackers Hangout Community Discord Invite:

🛠️ Stuff I Use 🛠️

🪛 Tools:

🫠 Soldering & Hot Air Rework Tools:

🔬 Microscope Setup:

About Me:

My name is Matt Brown and I'm an Hardware Security Researcher and Bug Bounty Hunter. This channel is a place where I share my knowledge and experience finding vulnerabilities in IoT systems.

- Soli Deo Gloria

💻 Social:

#righttorepair #jailbreak #firmware #iot #hacking

Hacking the Arlo Q Security Camera: Failed Promises and Data Security

Hacking the Arlo Q Security Camera: Firmware Extraction

Hacking the Arlo Q Security Camera: Bootloader Reverse Engineering

Rooting an Arlo Q Plus Camera (SSH 🔙🚪?!)

Hacking arlo

Arlo ddos hack

ARLO Q HD Video Security Camera: 2021 Update

Arlo Hackers

Locked out of Arlo account by Hackers

Arlo Q HD Security Camera

Integrating the Arlo Q camera with Samsung SmartThings

Best Unhackable Security Cameras of 2023

360° 100% wireless cameras better than Arlo pro hack luna 1080p or 720p

If left to my own... devices: playing with new Netgear Arlo Q security camera.

Arlo camera solar pier hack

#IP #cameras are #1 way for#hackers to #Steal #data

Arlo cameras take the L with disposable junk

Hardware Hacking Primer | Key Tips to Get You Started

Discovering a Hardcoded Root Password - Hacking the VStarcam CB73 Security Camera

Why My Arlo Camera Not Connecting to WiFi - Learn How to Fix it

Arlo Essential Camera not connecting to WiFi [QUICK FIX]

Caught On Arlo: Burglary in Progress + Arlo = 26 mos

Nobody thinks to do this for their home security cameras... 🤯

Arlo Q HD Indoor Security Camera with 2Way Talk

Комментарии

0:28:38

0:28:38

0:40:58

0:40:58

0:20:03

0:20:03

0:03:13

0:03:13

0:00:09

0:00:09

0:00:59

0:00:59

0:04:11

0:04:11

0:01:51

0:01:51

0:01:51

0:01:51

0:11:26

0:11:26

0:10:07

0:10:07

0:10:02

0:10:02

0:00:19

0:00:19

0:01:09

0:01:09

0:06:54

0:06:54

0:01:01

0:01:01

0:09:27

0:09:27

0:00:45

0:00:45

0:35:27

0:35:27

0:00:40

0:00:40

0:04:41

0:04:41

0:00:33

0:00:33

0:00:37

0:00:37

0:05:23

0:05:23