filmov

tv

Calculating Safety Stock: Protecting Against Stock Outs

Показать описание

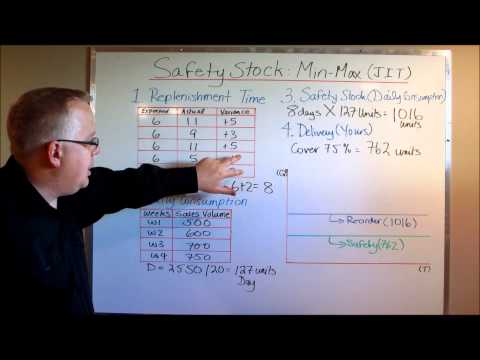

The following video explains how to calculate safety stock in order to avoid the high costs of inventory shortages and stock-outs. The video explains inventory replenishment times, daily consumption, safety stock thresholds and levels, and your company’s own time to market in terms of delivery.

A graph is provided that clearly shows what the reorder point should be and what the safety stock levels should be.

A working example is provided where a company tracks a number of inventory replenishment times, their own daily consumption levels, the safety stock amount they need to cover during these consumption periods and then finally, your company’s delivery times for finished goods to your customer base.

A graph is provided that clearly shows what the reorder point should be and what the safety stock levels should be.

A working example is provided where a company tracks a number of inventory replenishment times, their own daily consumption levels, the safety stock amount they need to cover during these consumption periods and then finally, your company’s delivery times for finished goods to your customer base.

Calculating Safety Stock: Protecting Against Stock Outs

6 Best Safety Stock Formulas: Calculation & Examples in Excel (Full TUTORIAL)

How To Figure Out Safety Stock

Safety Stocks: Don't Forget This

Safety Stock | Reorder Point ROP | Economic Order Quantity EOQ | Min Max Levels calculation in Excel

How to calculate a Reorder Point (ROP) in Inventory Management

How Do You Calculate Safety Stock and Reorder Points in Inventory Management? | Unleashed

What Is Safety Stock Inventory? | Rowtons Training by Laurence Gartside

Buffer Stock vs Safety Stock Explained

Safety Stock - Supply Chain In 3 Minutes

Safety Stock Formula: 4 Top Mistakes

Inventory Management - Video E

How to Calculate Inventory Reorder Points and Safety Stock Values

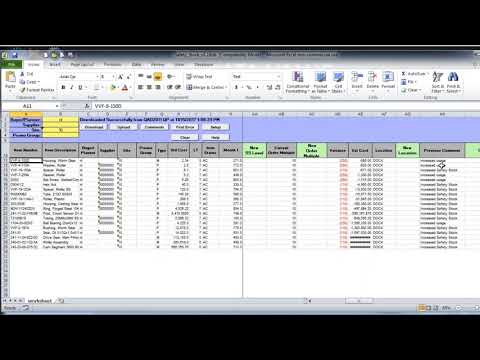

Calculating Safety Stock Level in QAD - 32 Soft

Safety Stock Overview | Safety stock in Supply Chain

4 Variables in Safety Stock Calculation

Calculating Safety Stock (Continuous Distribution) based on EOQ ReOrder Point (ROP)

Death by Safety Stock Safety Stock Calculations

Calculating safety stock by Amosoft

Safety Stock Calculation

5 FORECAST BASED INVENTORY MANAGEMENT: SAFETY STOCK

Reorder point (ROP) & Safety Stock - Inventory Management Calculations

Inventory Planning: Calculate Safety Stock/Reorder Point

Safety Stock Concept Formula Service Level

Комментарии

0:06:17

0:06:17

0:24:52

0:24:52

0:06:48

0:06:48

0:01:46

0:01:46

0:18:40

0:18:40

0:06:22

0:06:22

0:09:09

0:09:09

0:06:09

0:06:09

0:01:22

0:01:22

0:03:25

0:03:25

0:51:42

0:51:42

0:07:31

0:07:31

0:09:41

0:09:41

0:03:02

0:03:02

0:05:59

0:05:59

0:00:17

0:00:17

0:06:15

0:06:15

0:02:12

0:02:12

0:03:43

0:03:43

0:07:57

0:07:57

0:09:25

0:09:25

0:04:24

0:04:24

0:32:56

0:32:56

0:05:55

0:05:55