filmov

tv

Basics: Cleaning out a clogged nozzle!

Показать описание

As you 3D print more and more frequently, clogged or partially blocked nozzles actually get rarer as you learn how to avoid them. But if you do manage to get yourself a blocked nozzle, here's how to fix it!

Product links are affiliate links - I may earn a commission on qualifying purchases (at no extra cost to you)

Product links are affiliate links - I may earn a commission on qualifying purchases (at no extra cost to you)

Basics: Cleaning out a clogged nozzle!

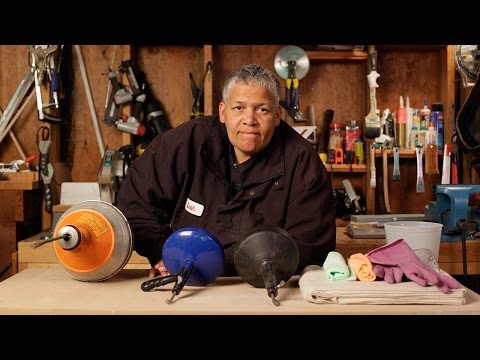

How to Unclog Any Drain | Ask This Old House

How Pipes Are Professionally Cleaned and Relined | Art Insider

How to Snake a Drain | Step by Step DIY Plumbing | Zillow

How to clean out a clogged nozzle - NoClogger The Must-Have 3D Printing Tool

Quick Fix For A Clogged Drain #cleaningtips #protips #cleanwithme

Water Softener Cleaning & Restore it Like New - Don't skip this EASY maintenance

How To Use a Toilet Snake Properly | Clogged Blocked Toilet Repair using Toilet Auger

How To Clear A Clogged 3D Printer Nozzle – ATM Quick Take | Digi-Key Electronics

How to Clean Gutters | Cleaning Tips | The Home Depot

How Your Home Plumbing Works (From Start to Finish) | GOT2LEARN

Creality Ender-3 Cleaning Out The Clogged Nozzle! (How to)

Metal fragment clogs the nozzle

Clearing a Blocked Drain on a ROOF | How to Use a Plumbing Snake

10 Methods to Clean Condensate Drains/Traps on Air Conditioners!

10 Reasons Why You'd FAIL a Plumbing Inspection! | GOT2LEARN

How to UNCLOG a KITCHEN SINK Guaranteed | DIY Plumbing

RV Black Tank Cleaning, Maintenance, Tips & Tricks - The Original Black Tank Master Class

How to clean out a clogged sink drain!

Hydro Jetting Service | Roto-Rooter

Using a BORESCOPE to CLEAN OUT a CLOGGED VENT PIPE

Clogged Plumbing Vent Symptoms - How To Fix Them

How To Unclog A Toilet With An Auger - DIY Plumbing - The Expert Plumber

How To Clean a Shower Head and Shower Drain

Комментарии

0:07:32

0:07:32

0:09:18

0:09:18

0:03:39

0:03:39

0:04:51

0:04:51

0:00:07

0:00:07

0:00:59

0:00:59

0:07:28

0:07:28

0:03:35

0:03:35

0:01:04

0:01:04

0:02:21

0:02:21

0:07:06

0:07:06

0:03:42

0:03:42

0:00:55

0:00:55

0:10:13

0:10:13

0:00:59

0:00:59

0:07:36

0:07:36

0:12:05

0:12:05

0:21:14

0:21:14

0:05:40

0:05:40

0:01:46

0:01:46

0:24:36

0:24:36

0:02:12

0:02:12

0:04:18

0:04:18

0:01:56

0:01:56