filmov

tv

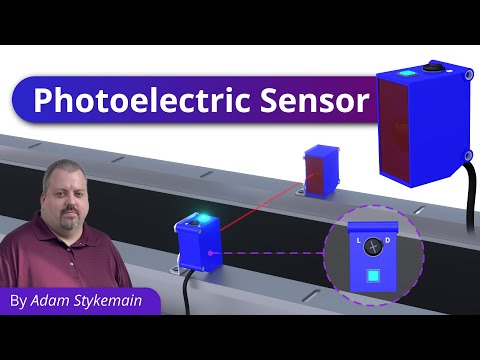

Photoelectric Sensor Wiring and Setup

Показать описание

=============================

▶ You can read the full post here

=============================

⌚Timestamps:

00:00 - Intro

00:18 - Mounting

01:17 - Wiring

02:42 - 1) Through-Beam

03:22 - 2) Retroreflective

03:51 - 3) Diffused

04:43 - troubleshooting

=============================

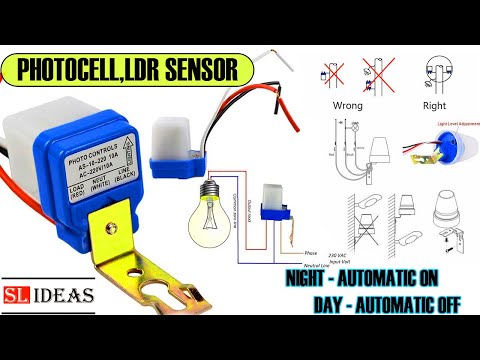

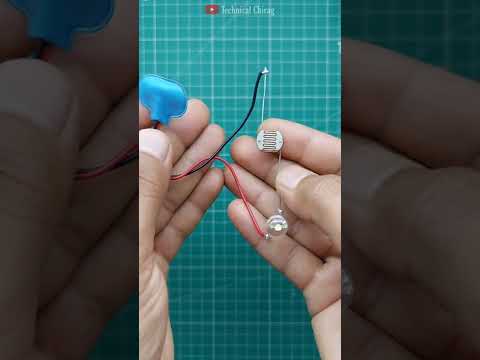

In this video, we will be talking about the wiring and setup of the 24-volt DC Through-Beam, Retroreflective, and Diffused photoelectric sensors. These are the three basic types of photoelectric sensors and they come in many different shapes and sizes.

Some of the larger photoelectric sensors have holes in the sensor body that can be used to mount the sensor and some of the smaller photoelectric sensors require some type of bracket to hold them in place.

You can buy premade brackets to mount these sensors and these brackets can be adjustable or non-adjustable.

A belt conveyor transporting an empty box will be used to explain how to set up each sensor. On this conveyor, the sensor will trigger the Motor Starter to start or stop the motor. We will also talk about troubleshooting these photoelectric sensors.

1) Through-Beam sensors have two separate devices, one is called the emitter and the other is called the receiver. The emitter is what sends the light out and the receiver is what catches the light.

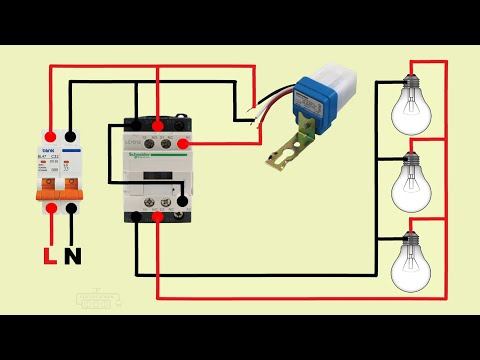

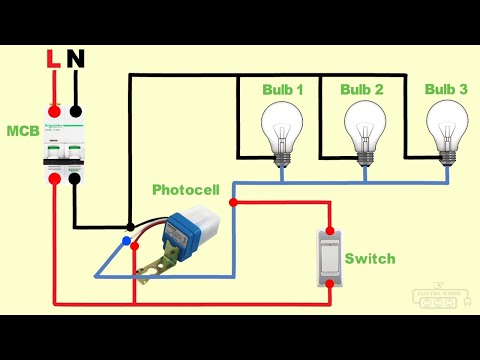

Both of these sensor devices will need to be connected to 24-volt DC power. The receiver will also be connected to the 24-volt DC Motor Starter coil.

To be safe, make sure the power is turned off before connecting any wires.

To connect the emitter of the Through-Beam sensor to 24-volt DC power, connect the brown wire to 24-volt DC positive, the blue wire to 24-volt DC negative, and the black wire to the 24-volt DC Motor Starter coil.

We will use a premade adjustable bracket to make mounting and aiming of the sensors easier.

With the Through-Beam sensor, use a straight edge to line up and mount the emitter and receiver, so they are straight across the conveyor belt from each other.

Adjust the sensor if needed and tighten everything down to lock the sensor in place.

To check alignment, block and unblock the sensor with your hand to make sure the sensor indicator light turns on and off.

2) Retroreflective sensor needs a reflector to work. Use a straight edge to line up and mount the sensor and the reflector, so they are straight across the conveyor belt from each other.

To check alignment, block and unblock the sensor with your hand to make sure the sensor indicator light turns on and off.

3) To mount the Diffused photoelectric sensor put the empty box on the conveyor where you want it to stop. Mount the sensor at the front edge of the box, adjust and tighten everything down.

Diffused sensors have a sensitivity adjustment screw. If the sensitivity is set too high the sensor might stay on all the time. If the sensitivity is set to low it might not turn on.

To set the sensitivity for this belt conveyor, put the box in front of the sensor in the middle of the conveyor belt. Adjust the sensitivity until the sensor indicator light just turns on with the box in this position.

To test out these sensors we will place an empty box on the conveyor belt and start the conveyor. If the photoelectric sensor is set up correctly the box will travel to the sensor, and then shut down the conveyor motor when it blocks the sensor.

If the conveyor does not start, the sensor might need to be adjusted or it might be dirty. Clean the lens of the sensor and check the alignment by blocking the sensor and watching the sensor indicator light to see if it turns off and on.

If the conveyor still does not start, look at the Motor Starter and block the sensor again. If the sensor is working correctly, you should be able to hear the Motor Starter contacts close.

If the motor only runs when the sensor is blocked, it is probably in dark-on mode. Flip the mode switch to light-on mode to correct this issue.

If the conveyor motor stays running, the sensor might be misaligned and in dark-on mode, the sensor or the sensor cable might be bad and will need to be replaced.

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #Photoelectric #Sensor

Комментарии

0:07:49

0:07:49

0:02:26

0:02:26

0:02:33

0:02:33

0:00:26

0:00:26

0:02:57

0:02:57

0:07:40

0:07:40

0:02:11

0:02:11

0:02:11

0:02:11

0:00:35

0:00:35

0:09:08

0:09:08

0:02:06

0:02:06

0:01:23

0:01:23

0:05:07

0:05:07

0:02:49

0:02:49

0:04:22

0:04:22

0:01:41

0:01:41

0:10:38

0:10:38

0:05:00

0:05:00

0:04:41

0:04:41

0:00:12

0:00:12

0:00:30

0:00:30

0:09:36

0:09:36

0:02:53

0:02:53

0:01:05

0:01:05