filmov

tv

Introduction to Lean Manufacturing. A New Aged Definition to Lean Manufacturing by Rever

Показать описание

Wondering what lean manufacturing is and how it can be applied to your products or service? In this video, we explain the concept in simple terms and look at how it differs from other forms of manufacturing. In it you’ll learn:

- A definition of lean manufacturing that’s easy to understand

- The key differences between lean manufacturing and mass production

- Why copying lean concepts won’t change underlying business processes

Having a clear definition of lean manufacturing is important because it will affect how you implement it in your production flow. Some people take a philosophical perspective that’s concerned with ‘creating value’ and ‘developing people’. If you focus on this definition, then you may struggle with the pragmatic process improvements and implementation aspects.

Others focus on the practical elements, describing it as a set of supply chain tools or a step-by-step process. Following this definition alone will likely mean that you’ll find the mindset and cultural changes difficult to implement. It can also be harder to get buy-in from upper management since this definition doesn’t convey the strategic long-term value.

We also hear inaccurate definitions that relate it to basic common sense or industrial engineering. These types of definition are guaranteed to set you up for failure since they don’t reflect what the concept is at all. So, this video is designed to address exactly what lean manufacturing is, as well as what it isn’t.

Lean is both an ideal and a means to achieve this ideal. The idea is to produce what the customer wants at the right time, quantity, and amount. Lean means producing nothing more and nothing less because this would either result in waste or poor customer experience. The means of achieving this ideal is the continuous practice of ‘Kaizen’ which involves developing people, improving processes, and maximizing value for the customer. This typically results in less waste, less burden, and less variation in output.

This approach is very different from mass production which attempts to reduce unit cost through economies of scale. Creating products in large batches leads to significant inventories which are costly to store and manage.

The definition we share in this video can help you communicate what lean manufacturing is to everyone in your company. Whether they work on the shop floor or in high-level management, it conveys the concept of ‘lean’ in a way that’s easy to understand. Hit like if you found this video helpful or subscribe to our channel for more lean management and continuous improvement ideas.

- A definition of lean manufacturing that’s easy to understand

- The key differences between lean manufacturing and mass production

- Why copying lean concepts won’t change underlying business processes

Having a clear definition of lean manufacturing is important because it will affect how you implement it in your production flow. Some people take a philosophical perspective that’s concerned with ‘creating value’ and ‘developing people’. If you focus on this definition, then you may struggle with the pragmatic process improvements and implementation aspects.

Others focus on the practical elements, describing it as a set of supply chain tools or a step-by-step process. Following this definition alone will likely mean that you’ll find the mindset and cultural changes difficult to implement. It can also be harder to get buy-in from upper management since this definition doesn’t convey the strategic long-term value.

We also hear inaccurate definitions that relate it to basic common sense or industrial engineering. These types of definition are guaranteed to set you up for failure since they don’t reflect what the concept is at all. So, this video is designed to address exactly what lean manufacturing is, as well as what it isn’t.

Lean is both an ideal and a means to achieve this ideal. The idea is to produce what the customer wants at the right time, quantity, and amount. Lean means producing nothing more and nothing less because this would either result in waste or poor customer experience. The means of achieving this ideal is the continuous practice of ‘Kaizen’ which involves developing people, improving processes, and maximizing value for the customer. This typically results in less waste, less burden, and less variation in output.

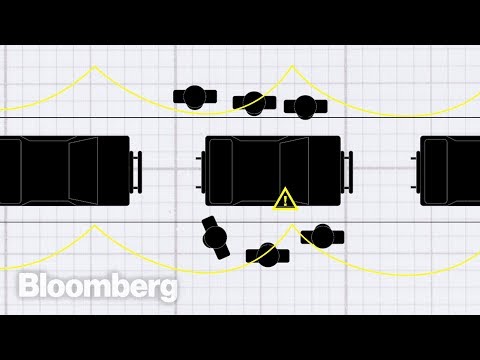

This approach is very different from mass production which attempts to reduce unit cost through economies of scale. Creating products in large batches leads to significant inventories which are costly to store and manage.

The definition we share in this video can help you communicate what lean manufacturing is to everyone in your company. Whether they work on the shop floor or in high-level management, it conveys the concept of ‘lean’ in a way that’s easy to understand. Hit like if you found this video helpful or subscribe to our channel for more lean management and continuous improvement ideas.

0:09:14

0:09:14

0:09:35

0:09:35

0:08:08

0:08:08

0:09:27

0:09:27

0:09:48

0:09:48

0:10:39

0:10:39

0:08:51

0:08:51

0:32:39

0:32:39

0:11:36

0:11:36

0:14:43

0:14:43

0:06:36

0:06:36

0:06:16

0:06:16

0:07:49

0:07:49

0:01:34

0:01:34

0:07:56

0:07:56

0:06:29

0:06:29

0:08:59

0:08:59

0:05:05

0:05:05

0:09:51

0:09:51

0:12:16

0:12:16

0:04:52

0:04:52

0:04:55

0:04:55

0:08:12

0:08:12

0:07:00

0:07:00