filmov

tv

Automatic Tool Changer vs. KUKA Robot | CNC Horizontal Boring Mill | FERMAT MACHINERY

Показать описание

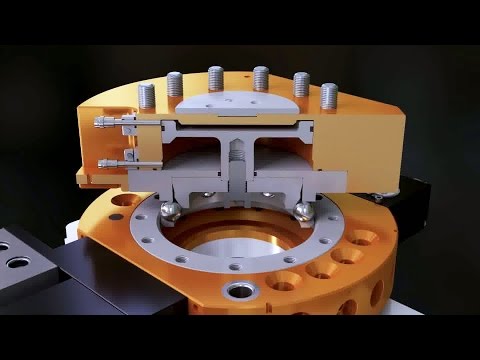

Automatic Tool Changer vs. KUKA Robot on CNC Horizontal Boring Mill.

Which one is faster?

There are still plenty of room for workers in modern factories: it’s just neither to their benefit nor to that of the manufacturer to expose them to unwanted physical burdens, spinal injuries, dismemberment, and other health risks.

Simple CNC machines work with a single tool. Turrets can work with a large number of tools. But if even more tools are required, then ATC is provided. An Automatic tool changer or ATC is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATC changes the tool very quickly, reducing the non-productive time. Generally, it is used to improve the capacity of the machine to work with a number of tools. It is also used to change worn out or broken tools. It is one more step towards complete automation.

The ATC can hold up to 40 tools which is not bad while the KUKA Robot can have 105 tools to work with or even more as long as it is within it's reach. A KUKA Robot used as an automatic changing system for tools and heads provides many benefits in the machining process. It has minimal maintenance or service interventions, gives you the possibility to change tools into various accessories and attachments and provides no interference in the work area normally encountered by the required rail of the traditional mechanical tool changer.

Which one is faster?

There are still plenty of room for workers in modern factories: it’s just neither to their benefit nor to that of the manufacturer to expose them to unwanted physical burdens, spinal injuries, dismemberment, and other health risks.

Simple CNC machines work with a single tool. Turrets can work with a large number of tools. But if even more tools are required, then ATC is provided. An Automatic tool changer or ATC is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATC changes the tool very quickly, reducing the non-productive time. Generally, it is used to improve the capacity of the machine to work with a number of tools. It is also used to change worn out or broken tools. It is one more step towards complete automation.

The ATC can hold up to 40 tools which is not bad while the KUKA Robot can have 105 tools to work with or even more as long as it is within it's reach. A KUKA Robot used as an automatic changing system for tools and heads provides many benefits in the machining process. It has minimal maintenance or service interventions, gives you the possibility to change tools into various accessories and attachments and provides no interference in the work area normally encountered by the required rail of the traditional mechanical tool changer.

0:01:53

0:01:53

0:00:53

0:00:53

0:00:51

0:00:51

0:00:23

0:00:23

0:00:41

0:00:41

0:00:39

0:00:39

0:02:05

0:02:05

0:00:36

0:00:36

0:00:21

0:00:21

0:00:20

0:00:20

0:00:27

0:00:27

0:00:55

0:00:55

0:05:52

0:05:52

0:00:32

0:00:32

0:02:00

0:02:00

0:01:39

0:01:39

0:01:46

0:01:46

0:01:10

0:01:10

0:00:16

0:00:16

0:00:43

0:00:43

0:00:54

0:00:54

0:02:56

0:02:56

0:00:11

0:00:11

0:01:01

0:01:01