filmov

tv

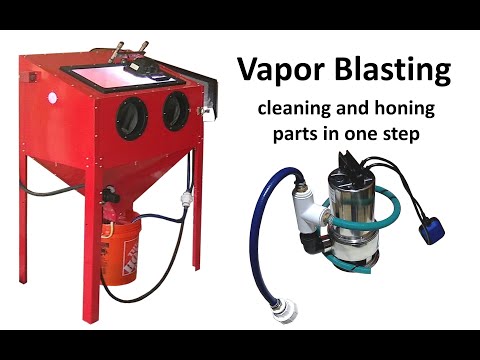

Building a DIY vapor blaster THAT WORKS

Показать описание

In this video I present you the DYI vapor blaster I built. I bought a regular sand blasting cabinet and converted it to a vapor blaster to clean engine parts etc.

And it seems to work very well.

I use glass beads as blasting media. I am still experimenting with air pressure and glass beads ratio to have the best finish.

chapters:

0:00 - setup presentation

2:54 - removing valve cover for testing

3:42 - vapor blasting

6:42 - amazing results

I will use this machine on future restoration projects so subscribe if you don't want to miss that.

Leave your questions or remarks in the comments below I will be happy to answer them.

Thanks for watching!

And it seems to work very well.

I use glass beads as blasting media. I am still experimenting with air pressure and glass beads ratio to have the best finish.

chapters:

0:00 - setup presentation

2:54 - removing valve cover for testing

3:42 - vapor blasting

6:42 - amazing results

I will use this machine on future restoration projects so subscribe if you don't want to miss that.

Leave your questions or remarks in the comments below I will be happy to answer them.

Thanks for watching!

DIY Vapor Blaster Build for Less than $500!

Should You Convert a Harbor Freight Sand Blaster into a Vapor Blaster?

DIY Vapor Blasting... What NO ONE Tells You

Building a DIY vapor blaster THAT WORKS

TESTING THE $336- DIY VAPOR BLASTER.... how to build

Cheapest DIY Vapor Blaster Guide | How To Build The Ultimate Budget Vapour Hone

What Would You Vapor Blast?

Building And Testing A Homemade Vapor Blaster!

DIY Vapor Blaster Build & Setup!

DIY Budget Vapor Blasting Cabinet

Harbor Freight Vapor Honing - Wet Blasting Cabinet Modifications- HTMR Bare Bones Build @HTMR

How-To: WOOD DIY Vapor Blaster Plans 42x30 & 60x40

DIY Vapor Blasting Cabinet with Pressure Washer

TWICE AS FAST! HTMR Vapor/Dry Blast Gun

DIY Wood Vapor Blaster From Australia

Vapor Honing Setup Harbor Freight 40 lb Sand Blast Cabinet Mods with Complete Parts List

DIY Vapor Blaster Pump Setups

A simple DIY Vapor Blaster

Diy vapour blasting cabinet Build

DIY HF Vapor Blaster - 2 year update

how to make a DIY vapor blaster and clean aluminum HTMR field trip

DIY Vapour Blaster

DIY Vapour Blaster Build, Aussie/NZ components and specs

Vapor Blasting / Honing Harbor Freight Sand Blast Cabinet Glass Film Flex Hose & V2 Nozzle Upgra...

Комментарии

0:09:09

0:09:09

0:00:31

0:00:31

0:04:59

0:04:59

0:08:05

0:08:05

0:03:37

0:03:37

0:17:18

0:17:18

0:00:20

0:00:20

0:29:30

0:29:30

0:10:41

0:10:41

0:20:06

0:20:06

0:03:04

0:03:04

0:50:44

0:50:44

0:09:14

0:09:14

0:30:00

0:30:00

0:02:09

0:02:09

0:30:10

0:30:10

0:08:28

0:08:28

0:09:22

0:09:22

0:01:34

0:01:34

0:03:41

0:03:41

0:08:57

0:08:57

0:08:27

0:08:27

0:15:27

0:15:27

0:33:13

0:33:13