filmov

tv

COOLING TOWER CALCULATIONS: STEP BY STEP GUIDE! INDUSTRIAL APPLICATION

Показать описание

COOLING TOWER CALCULATIONS: STEP BY STEP GUIDE!

—————————————————————-

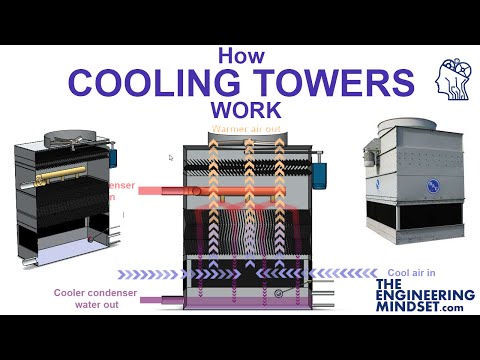

In order to lower the temperature of the water, air and water are brought into direct contact in a cooling tower, a specialized heat exchanger. A little amount of water evaporates during this process, bringing the temperature of the water flowing through the tower down.

Approach: is the difference between the air's wet-bulb temperature and the temperature of the cold water leaving the tower.

Wet Bulb temperature: The lowest temperature that water can supposedly attain through evaporation is wet bulbs.

Cooling range: The temperature differential between the hot water entering the tower and the cold water leaving the tower is known as the cooling range.

Blowdown: is the intentional discharge of water from the system to regulate salt or other impurity concentrations in the circulating water rate or l/min.

Cycles of concentration (COC): compare dissolved solids in makeup water with solids concentrated through evaporation in the circulating water.

Drift: The term "drift" refers to water that has been released into the airflow and released into the atmosphere. Water lost through evaporation is not considered a part of drift loss.

· Drift loss (D) = 0.3 to 1.0 percent of circulating water for a natural draft tower

· Drift loss (D) = 0.1 to 0.2 percent of circulating water for a typical induced draft tower

Makeup: is the volume of water necessary to make up for typical losses brought on by blow down drift, and evaporation.

To calculate cooling tower mass balance:

a. Get the wet bulb temperature.

b. Calculate the Cooling tower efficiency.

c. Calculate water lost through Evaporation.

d. Calculate Blown down

e. Calculate Water droplets or drift loss

f. Calculate: Make up water.

Thanks for watching

------------------------------------------------------------------------------------------------------------------

Access Ready Information for you:

Octave, Coco Simulation, DWSIM Simulation

Octave Lessons / Tutorials:

Octave Lessons – Process Control

Coco Simulation:

DWSIM Simulation:

—————————————————————-

In order to lower the temperature of the water, air and water are brought into direct contact in a cooling tower, a specialized heat exchanger. A little amount of water evaporates during this process, bringing the temperature of the water flowing through the tower down.

Approach: is the difference between the air's wet-bulb temperature and the temperature of the cold water leaving the tower.

Wet Bulb temperature: The lowest temperature that water can supposedly attain through evaporation is wet bulbs.

Cooling range: The temperature differential between the hot water entering the tower and the cold water leaving the tower is known as the cooling range.

Blowdown: is the intentional discharge of water from the system to regulate salt or other impurity concentrations in the circulating water rate or l/min.

Cycles of concentration (COC): compare dissolved solids in makeup water with solids concentrated through evaporation in the circulating water.

Drift: The term "drift" refers to water that has been released into the airflow and released into the atmosphere. Water lost through evaporation is not considered a part of drift loss.

· Drift loss (D) = 0.3 to 1.0 percent of circulating water for a natural draft tower

· Drift loss (D) = 0.1 to 0.2 percent of circulating water for a typical induced draft tower

Makeup: is the volume of water necessary to make up for typical losses brought on by blow down drift, and evaporation.

To calculate cooling tower mass balance:

a. Get the wet bulb temperature.

b. Calculate the Cooling tower efficiency.

c. Calculate water lost through Evaporation.

d. Calculate Blown down

e. Calculate Water droplets or drift loss

f. Calculate: Make up water.

Thanks for watching

------------------------------------------------------------------------------------------------------------------

Access Ready Information for you:

Octave, Coco Simulation, DWSIM Simulation

Octave Lessons / Tutorials:

Octave Lessons – Process Control

Coco Simulation:

DWSIM Simulation:

0:04:59

0:04:59

0:07:48

0:07:48

0:07:51

0:07:51

0:37:16

0:37:16

0:00:16

0:00:16

0:01:06

0:01:06

0:06:54

0:06:54

0:16:04

0:16:04

0:17:52

0:17:52

0:00:39

0:00:39

0:11:44

0:11:44

0:02:45

0:02:45

0:15:10

0:15:10

0:03:04

0:03:04

0:34:00

0:34:00

0:05:05

0:05:05

0:13:00

0:13:00

0:10:03

0:10:03

0:09:46

0:09:46

0:18:05

0:18:05

1:01:53

1:01:53

0:37:16

0:37:16

0:35:28

0:35:28

0:02:21

0:02:21