filmov

tv

Matec Washing and Classification Plant

Показать описание

Frontline Machinery’s Daryl Todd recently had the opportunity to tour one of Matec’s recent wash plant builds for Towen’s Waste Management in the UK.

Wash plants boost operations by increasing the value of raw materials while reducing waste and pollutants from mining, C&D recycling, hydro excavation, and aggregate applications.

Matec Washing Systems use advanced filtration techniques to remove impurities and contaminants from water, making it suitable for reuse. By using a Matec wash plant, you have the ability to separate the sand and gravel from dirt, clay, and other debris, providing a multitude of cleaner end specs for reusing, repurposing, and reselling.

This wash plant includes:

Aggretec: Effective in applications with raw materials. Imagine how convenient it would be to have a Sandtec, a Screentec, a feeding hopper, and 3, 4, or more conveyors in a single machine.

Screentec: Washes and separates materials into reusable end products, such as gravel, coal, crushed stone, slag, recycled materials, and concrete, with high efficiency.

Scrubtec: Scrubtec is best suited for the C&D sector, as it achieves top-class performance when scrubbing aggregates, lights, and other floating materials. It is also ideal for aggregates and mined materials with high clay content.

Attritec: Attritec attrition cells are used to effectively remove the pollutants on the surface of sand in contaminated slurries by scrubbing. attrition cells are an ideal step to be implemented before the hydrocyclonic process of the slurry

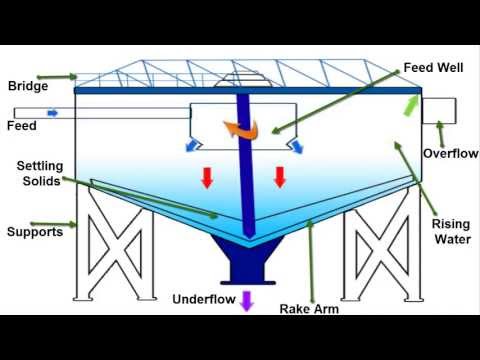

Filter press: Produces dry cakes with 15% residual moisture and recover 90% of water, occupying the minimum amount of space.

Wash plants boost operations by increasing the value of raw materials while reducing waste and pollutants from mining, C&D recycling, hydro excavation, and aggregate applications.

Matec Washing Systems use advanced filtration techniques to remove impurities and contaminants from water, making it suitable for reuse. By using a Matec wash plant, you have the ability to separate the sand and gravel from dirt, clay, and other debris, providing a multitude of cleaner end specs for reusing, repurposing, and reselling.

This wash plant includes:

Aggretec: Effective in applications with raw materials. Imagine how convenient it would be to have a Sandtec, a Screentec, a feeding hopper, and 3, 4, or more conveyors in a single machine.

Screentec: Washes and separates materials into reusable end products, such as gravel, coal, crushed stone, slag, recycled materials, and concrete, with high efficiency.

Scrubtec: Scrubtec is best suited for the C&D sector, as it achieves top-class performance when scrubbing aggregates, lights, and other floating materials. It is also ideal for aggregates and mined materials with high clay content.

Attritec: Attritec attrition cells are used to effectively remove the pollutants on the surface of sand in contaminated slurries by scrubbing. attrition cells are an ideal step to be implemented before the hydrocyclonic process of the slurry

Filter press: Produces dry cakes with 15% residual moisture and recover 90% of water, occupying the minimum amount of space.

0:03:37

0:03:37

0:05:13

0:05:13

0:01:58

0:01:58

0:01:04

0:01:04

0:02:16

0:02:16

0:01:24

0:01:24

0:01:40

0:01:40

0:01:00

0:01:00

0:01:45

0:01:45

0:02:44

0:02:44

0:02:41

0:02:41

0:00:55

0:00:55

0:04:26

0:04:26

0:01:57

0:01:57

0:03:06

0:03:06

0:02:54

0:02:54

0:01:12

0:01:12

0:06:15

0:06:15

0:03:21

0:03:21

0:03:41

0:03:41

0:00:27

0:00:27

0:02:31

0:02:31

1:02:26

1:02:26

0:03:01

0:03:01