filmov

tv

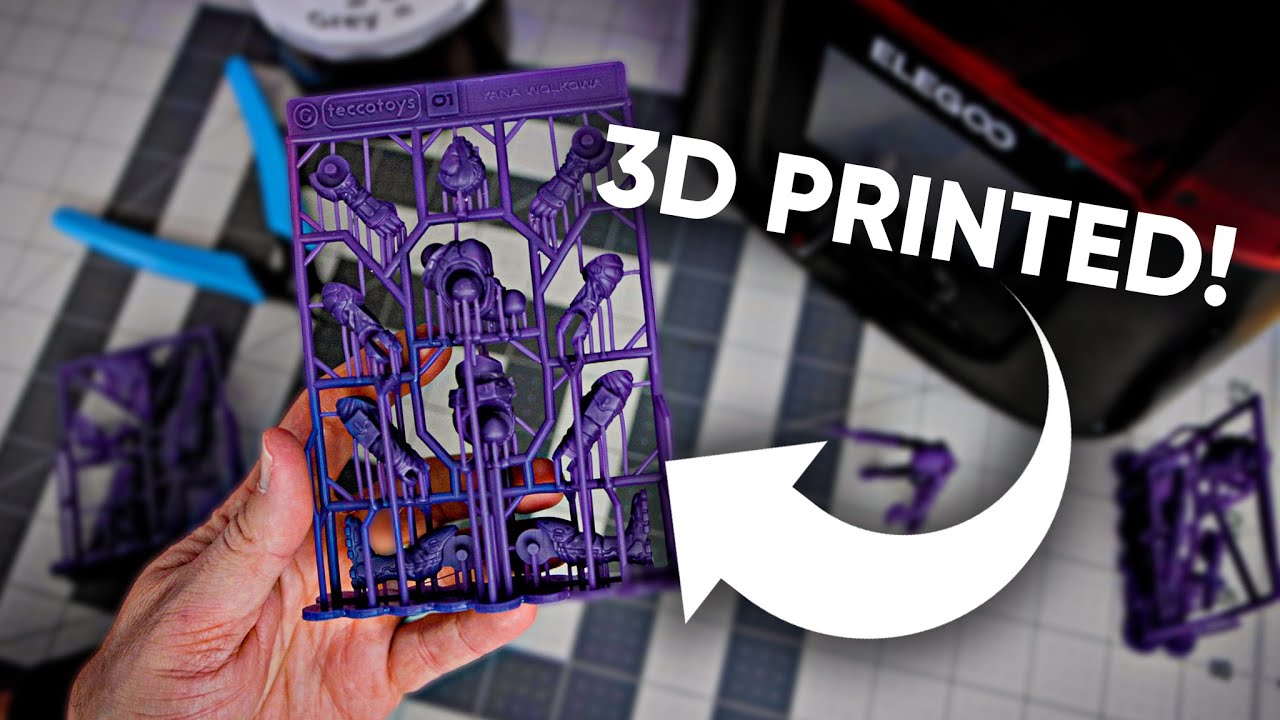

3D Printed Action Figures!!

Показать описание

This is officially a dream project come true. Attempting to 3D Print articulating action figures + Resin Stacking!

Thanks to Elegoo for Sponsoring today's video ➜

Make your own Resin 3D Printing Timelapses with Resinlapse ➜

Print your own Action Figures from TeccoToys

________________________________________________

Interested in other resin 3D Printers?

Peopoly Phenom ➜

Epax X10 ➜

________________________________________________

Some Additional Items you will want to consider for Resin 3D Printing ➜

________________________________________________

Interested in getting a 3D Printer? Here are some that I use ➜

TinyMachines3D.com

________________________________________________

_______________________________________________

________________________________________________

________________________________________________

Thanks for watching!

SEND STUFF TO ➜

Uncle Jessy

PO BOX 629

25 Goodburlet RD

Henrietta, NY 14467

#3DPrinting #Resin #Toys

Thanks to Elegoo for Sponsoring today's video ➜

Make your own Resin 3D Printing Timelapses with Resinlapse ➜

Print your own Action Figures from TeccoToys

________________________________________________

Interested in other resin 3D Printers?

Peopoly Phenom ➜

Epax X10 ➜

________________________________________________

Some Additional Items you will want to consider for Resin 3D Printing ➜

________________________________________________

Interested in getting a 3D Printer? Here are some that I use ➜

TinyMachines3D.com

________________________________________________

_______________________________________________

________________________________________________

________________________________________________

Thanks for watching!

SEND STUFF TO ➜

Uncle Jessy

PO BOX 629

25 Goodburlet RD

Henrietta, NY 14467

#3DPrinting #Resin #Toys

You have to 3D Print this Toy!

Before you buy the Resione Tough74

Awesome 3D Printed Toys

Will the Creality Sonic Pad let you 3D Print Action Figures?

I Made The World's Smallest Marvel Legends Figures!

The Best Resin for 3D Printed Action Figures?

Magnetic Dummy 13 Multi Jointed Action Figures lucky 13 3D printed Toys #actionfiguretoys

3D Printed Iron Man !! #acdc #lego #marvel #ironman

3D Print and Design Your Own Funko Pop Figurines! #bambu #3dprinting #bambu #teacher #3dprintedtoys

3D Printing Action Figures (2023)

Details on profile! #actionfigure #titan13toy #t13 #toy #stikbot #dummy13 #lego

3D-Printed Action Figures from DOOB 3D: Your New Favorite Selfie | Mashable

How to 3D-Print Your Own Marvel Legends Accessories! (Action Figure Props and Furniture)

Raw 3D Print Quality Finally Surpasses Retail Toys | Elegoo Centauri Carbon | Do3D Knuckles #Sonic 3

3D Printed Action Figure - Resin VS PLA #jlc3dp

3d Printed Articulated Dragon - Ender 5 S1 Unboxing

3D Printing Action Figures? Meet Dummy 13! (Insane Toy Designs)

eSUN PLA+ 3Dprinted Pokemon kyogre bulbasaur #esun#toys #3dprinting #3dprinted

LEGO Spider-Man 3d printed #3d #shortvideo #3dprinting #lego #spiderman

3D Printing my own action figures with Creality Ender-3 S1

How to 3D-Scan Action Figures with the Revopoint MINI

3D Printed Build Your Own Katana Kit

Can You 3D Print Marvel Legends Action Figures? (Sort of!)

Teenage Mutant Ninja Turtles🐢 3D Printed on Bambu lab p1s with Sunlu pla #shorts #tmnt tmnt

Комментарии

0:09:14

0:09:14

0:10:08

0:10:08

0:20:42

0:20:42

0:13:19

0:13:19

0:05:25

0:05:25

0:13:22

0:13:22

0:00:16

0:00:16

0:00:53

0:00:53

0:00:30

0:00:30

0:10:00

0:10:00

0:00:27

0:00:27

0:03:18

0:03:18

0:10:22

0:10:22

0:00:30

0:00:30

0:09:10

0:09:10

0:00:32

0:00:32

0:12:26

0:12:26

0:00:16

0:00:16

0:00:48

0:00:48

0:10:24

0:10:24

0:03:24

0:03:24

0:00:21

0:00:21

0:08:29

0:08:29

0:00:12

0:00:12