filmov

tv

UMM OUR BEER WALK IN IS WARM

Показать описание

This started during the last heatwave of the year.

Please consider supporting my channel by

By purchasing tools via my affiliate links below at TRUTECHTOOLS.COM and use the offer code BIGPICTURE to save 8% on your total purchase (exclusions apply)

Social Media

Mailing Address

HVACR VIDEOS

12523 LIMONITE AVE.

440 - 184

MIRA LOMA, CA. 91752

Please consider supporting my channel by

By purchasing tools via my affiliate links below at TRUTECHTOOLS.COM and use the offer code BIGPICTURE to save 8% on your total purchase (exclusions apply)

Social Media

Mailing Address

HVACR VIDEOS

12523 LIMONITE AVE.

440 - 184

MIRA LOMA, CA. 91752

UMM OUR BEER WALK IN IS WARM

'ARE YOU SINGLE' #shorts

Hey Bobby, look look I'm American!

Famous Vine Stars now...😳😟

THE FILTER WAS SUPPOSED TO BE ON ME NOT HER 🤣 #shorts

Riley said what he had to said 😭💀

'It's Just A Prank'

semaluhtounuyulohowwah

Freddy fazbear ur ur ur ur

Cheap Joke

Am I wrong? 😬 #shorts

Met this strange Vietnam bloke 🤣🤣 @hoeyfarmer

I'M SORRY I JUST NEED ONE MINUTE TO MAKE SURE I LOOK PRETTY #movie #movieclip

Happy birthday, Grimace!

He Didn't Even Hesitate 😳 #shorts #comedy

Breathe in…

I’m Petty Yeah Yeah I’m petty 💕

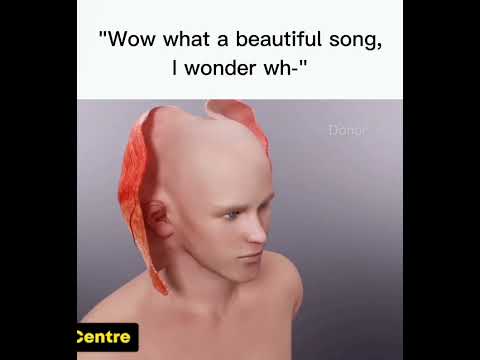

Misheard Lyrics #TheManniiShow.com/series

no

Kid Gets Caught Flipping Off His Mom #Hilarious 🖕🏿

Would you punch her for 1 Million dollars 💵!?? (1,000,000$)

Brother Tastes Alcohol For The First Time On 21st Bday

Bro ordered 50 pizzas... so I used Facemoji #shorts

Funky Town

Комментарии

0:31:06

0:31:06

0:00:28

0:00:28

0:00:11

0:00:11

0:00:23

0:00:23

0:00:16

0:00:16

0:00:17

0:00:17

0:00:06

0:00:06

0:00:06

0:00:06

0:00:06

0:00:06

0:01:00

0:01:00

0:00:34

0:00:34

0:00:30

0:00:30

0:00:13

0:00:13

0:00:18

0:00:18

0:00:26

0:00:26

0:00:31

0:00:31

0:00:07

0:00:07

0:00:33

0:00:33

0:00:16

0:00:16

0:00:09

0:00:09

0:00:19

0:00:19

0:00:36

0:00:36

0:00:38

0:00:38

0:00:17

0:00:17