filmov

tv

Chrome Finish on Plastic- Did I Find the Answer?

Показать описание

This week I tackle trying to achieve a mirror finish on our hood ornament reproductions from our carnival ride restoration.

Testing various finishes in search of the ultimate mirror chrome finish achievable in the home shop with commonly available items.

As an Amazon Associate I earn from qualifying purchases.

(paid links)

--------------------------------------------------------------------------------------------------------------------------------------------------

Know of a ride that needs rescued?

---------------------------------------------------------------------------------------------------------------------------------------------------

Testing various finishes in search of the ultimate mirror chrome finish achievable in the home shop with commonly available items.

As an Amazon Associate I earn from qualifying purchases.

(paid links)

--------------------------------------------------------------------------------------------------------------------------------------------------

Know of a ride that needs rescued?

---------------------------------------------------------------------------------------------------------------------------------------------------

Chrome Finish on Plastic- Did I Find the Answer?

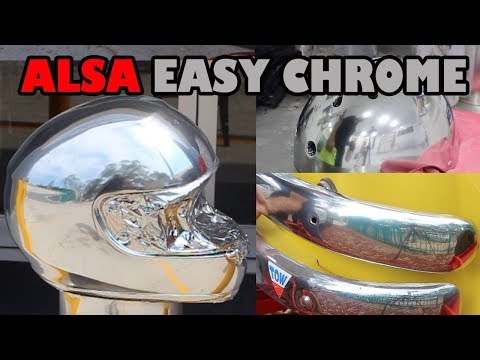

Easy Chrome Brush or Spray on Chrome

Testing 4 Different Brands Of Chrome Paint For Plastic Models

DIY Chrome Kit

Spray Paint Chrome Showdown Revell Rustoleum Duplicolor Krylon IronLak Review Scale Model How To

Chrome Plating on Plastic- Pre Treatment in process

Few people know this SECRET idea of chrome plastic! DIY Simple Chemistry

Chrome on plastic

Nickel plating chrome solution no need activator & no need buffing (GAROL MTV)

Restoration Old Car Parts | Spray Chrome Paint | Hydro Chrome | Mirror Like finish | #beforeandafter

Chrome Plating - Real Chrome On Any surface!

Gemini's chrome finish on formed plastic

Is Chrome Spray Paint Worth the Hype?

Chrome Paint Shootout | Fixed It Garage

How To Strip Chrome (quickly!) from Plastic Parts

How To Chrome Plastic? - LearnToDIY360.com

EASY CHROME KIT IN SPRAYS

The Best Chrome For Plastic Models - Electroplating Powder Test

GO CHROME Easy chrome effect tested with airbrush UK

Easy Chrome Finish for 3D Printed Parts

Restore your Chrome Auto Parts in Your Kitchen Sink - New home chroming system

Removing chrome finish from plastic parts

Chrome at any plastic matel.

Automatic plastic water plating line for plastic parts, chrome plated bottle covers, auto parts.

Комментарии

0:14:24

0:14:24

0:09:40

0:09:40

0:33:58

0:33:58

0:03:14

0:03:14

0:28:38

0:28:38

0:00:13

0:00:13

0:13:19

0:13:19

0:03:29

0:03:29

0:00:49

0:00:49

0:00:11

0:00:11

0:02:10

0:02:10

0:02:30

0:02:30

0:11:38

0:11:38

0:12:15

0:12:15

0:01:48

0:01:48

0:02:01

0:02:01

0:03:06

0:03:06

0:20:42

0:20:42

0:03:54

0:03:54

0:01:15

0:01:15

0:02:58

0:02:58

0:02:42

0:02:42

0:00:16

0:00:16

0:00:22

0:00:22