filmov

tv

PLC vs SCADA: Understanding the Differences

Показать описание

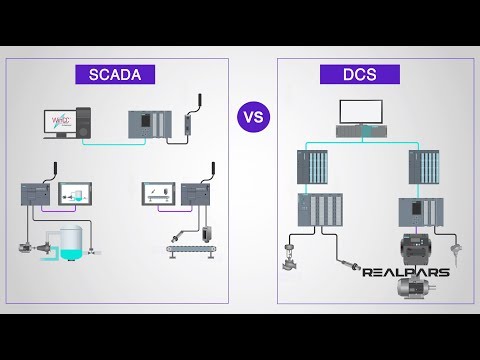

In this video, we will delve into the key differences between Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems. PLCs are essential for automation and controlling processes in a manufacturing environment, while SCADA systems gather, analyze, and present real-time data for monitoring and decision-making. PLCs are typically used for controlling individual machines or processes, while SCADA systems are used for supervisory control of entire systems or plants. PLCs rely on ladder logic programming to execute specific tasks, whereas SCADA systems use human-machine interface (HMI) software to visualize and manage complex processes. Understanding the distinctions between PLCs and SCADA systems is crucial for engineers, technicians, and anyone involved in automation and control systems. Watch this video to gain a comprehensive understanding of the functionalities and applications of both technologies. Don't forget to like, share, and subscribe for more informative content on industrial automation and technology. Let us know in the comments which topic you would like us to cover next!

#plcprogramming #SCADA #Automation #IndustrialControl #Differences #Engineering #Technology #PLCvsSCADA #PLC #SCADA #industrialautomation #controlsystems #automation #engineering #technology #PLCprogramming #SCADAsoftware #manufacturing #IIoT #digitaltransformation #processcontrol #smartfactory #sensors #IoT #HMI #robots #industry40

Stay tuned for more educational videos on our channel!

#plcprogramming #SCADA #Automation #IndustrialControl #Differences #Engineering #Technology #PLCvsSCADA #PLC #SCADA #industrialautomation #controlsystems #automation #engineering #technology #PLCprogramming #SCADAsoftware #manufacturing #IIoT #digitaltransformation #processcontrol #smartfactory #sensors #IoT #HMI #robots #industry40

Stay tuned for more educational videos on our channel!

0:03:26

0:03:26

0:04:54

0:04:54

0:08:09

0:08:09

0:07:13

0:07:13

0:03:09

0:03:09

0:01:39

0:01:39

0:11:03

0:11:03

0:06:02

0:06:02

0:12:10

0:12:10

0:07:48

0:07:48

0:09:16

0:09:16

0:15:11

0:15:11

0:00:59

0:00:59

0:07:54

0:07:54

0:12:10

0:12:10

0:20:32

0:20:32

0:08:35

0:08:35

0:01:01

0:01:01

0:05:35

0:05:35

0:07:08

0:07:08

0:11:23

0:11:23

0:10:58

0:10:58

0:05:48

0:05:48

0:06:00

0:06:00