filmov

tv

Reduce Lathe/Mill Head Flexing - Grizzly G4015 Modification

Показать описание

This is how I added extra stiffness to my milling process. The Grizzly uses a friction head locking system that I thought could be improved.

Reduce Lathe/Mill Head Flexing - Grizzly G4015 Modification

A wonderful technique that every machinist should know .

Lathe Machine Actual video accidents #shorts #short

Lathe Milling Head

Top 10 DIY Lathe Mill Upgrades to my Harbor Freight 3-in-1 Mill Lathe Combo Machine

Rigid Mini Lathe Upgrade | Tapered Roller Bearings, Solid Tool Post, Brass Gib Strips Mod

How to Operate the Combo Metal Lathe Mill Drill HQ500 HQ800 - WMTCNC

New (old) Mini Lathe Mill Combo Machine Smithy CB-1220 XL

Lathe Mill Combo Buyer's Guide

3 months of modifications to a Champion mill

Mini Lathe Headstock Rigidity Upgrade

Why Would You Ever Use CONVENTIONAL Milling??? | Climb vs Conventional

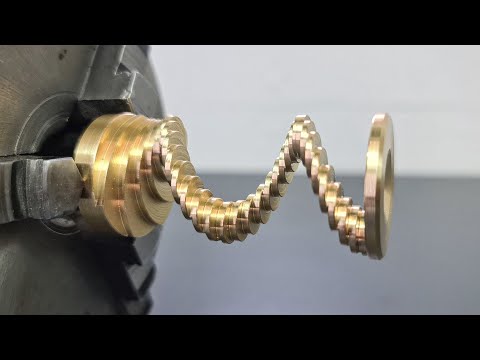

Making a Crazy Part on the Lathe - Manual Machining

Forget Milling machine - Now make gears on your Lathe

CRAFTEX B2229L (BUSYBEE CX615, GRIZZLY G9729) LATHE MILL COMBO SAMPLE CUT

High Speed WIre Rod Reducing Mill 110m/s Rolling Speed

Drill, Thread, and Chamfer with 1 Tool

'CRAFTEX' Combination Lathe/Mill, bent quill?

Lathe Machine's Gear Head Working

6 FEET AUTOMATIC LATHE MACHINE | Call 8195951515

reducing a square blank to cylinder on lathe machine. wood turning art in teak wood. woodworking diy

Laser cutting steel plate

FULLTONTECH 2300mm VTL with 90 degree milling head 2

Turning a Brake Drum on a Small Lathe Mill Drill

Комментарии

0:11:46

0:11:46

0:04:27

0:04:27

0:00:15

0:00:15

0:04:29

0:04:29

0:12:24

0:12:24

0:12:37

0:12:37

0:03:59

0:03:59

0:04:07

0:04:07

0:05:26

0:05:26

0:12:49

0:12:49

0:12:39

0:12:39

0:03:37

0:03:37

0:04:15

0:04:15

0:00:58

0:00:58

0:00:20

0:00:20

0:00:16

0:00:16

0:00:23

0:00:23

0:00:58

0:00:58

0:00:16

0:00:16

0:00:15

0:00:15

0:00:15

0:00:15

0:00:15

0:00:15

0:00:16

0:00:16

0:17:06

0:17:06