filmov

tv

BEARINGS BASICS and Bearing Life for Mechanical Design in 10 Minutes!

Показать описание

Rating Life,

Bearing Load Life,

Rated Reliability,

Catalog Load Rating.

0:00 Bearings Purpose

0:32 Bearing Components

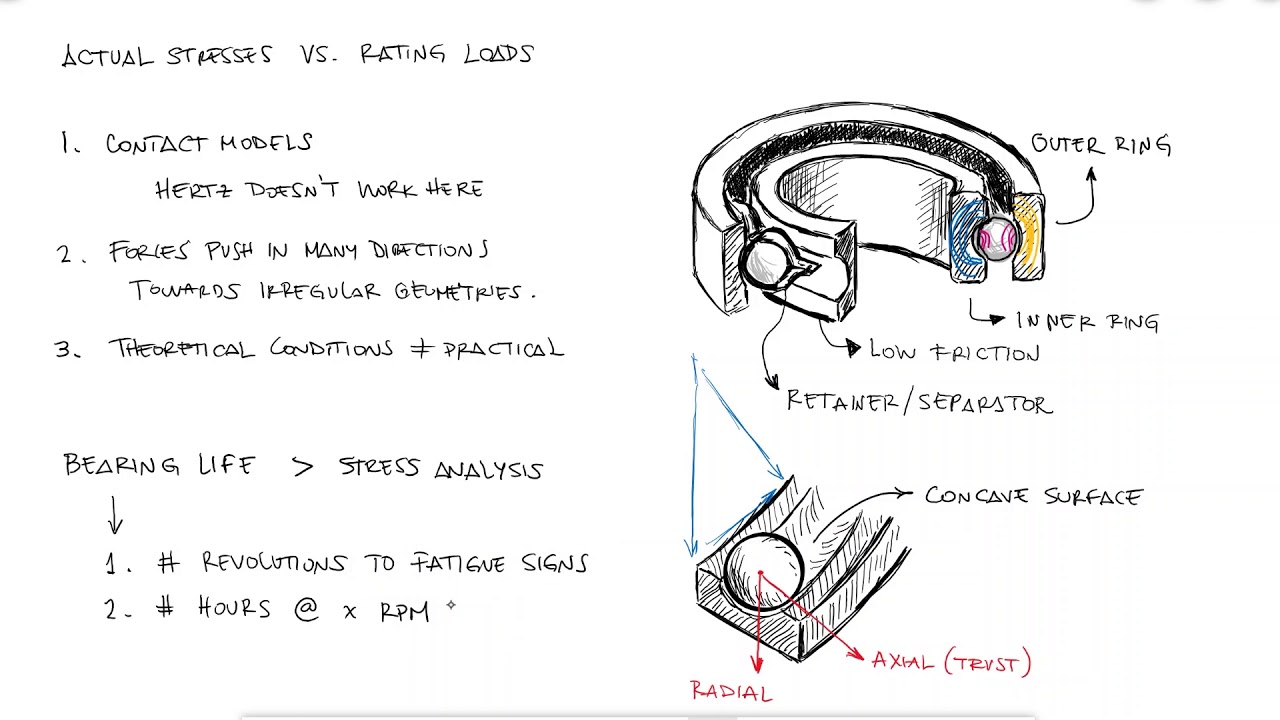

2:10 Rating Loads

3:26 Bearing Life

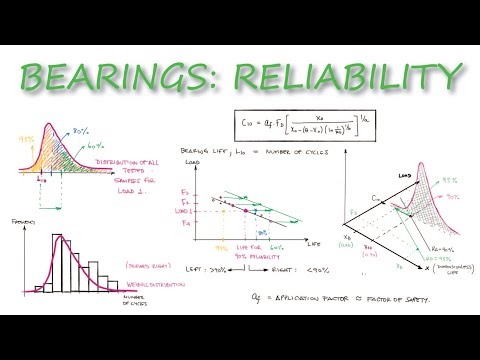

3:54 Rating Life

5:10 Catalog Load Rating

7:12 Rating Life: Hours vs. Cycles

7:37 Bearing Life Example

Previous Video: Gear Pitting - Surface Contact Stress Fatigue Failure in Just Over 10 Minutes

Next Video: Bearings Reliability and Bearings Selection in Just Over 10 Minutes

_____________________________________________

Other "Mechanical Engineering Design 1" Links:

Bearing Load Life,

Rated Reliability,

Catalog Load Rating.

0:00 Bearings Purpose

0:32 Bearing Components

2:10 Rating Loads

3:26 Bearing Life

3:54 Rating Life

5:10 Catalog Load Rating

7:12 Rating Life: Hours vs. Cycles

7:37 Bearing Life Example

Previous Video: Gear Pitting - Surface Contact Stress Fatigue Failure in Just Over 10 Minutes

Next Video: Bearings Reliability and Bearings Selection in Just Over 10 Minutes

_____________________________________________

Other "Mechanical Engineering Design 1" Links:

BEARINGS BASICS and Bearing Life for Mechanical Design in 10 Minutes!

What is Bearing? Types of Bearings and How they Work?

GCSE Maths - What are Bearings?

What type of bearing do you need? | KRAMP

Types of bearings | Engineering | Mechanical Maintenance | Rotary equipment | information of bearing

Basics and Types of Bearings [Common Types]

Bearings RELIABILITY and Bearings SELECTION in Just Over 10 Minutes!

What are bearings?

Types of Bearings 📌

Tribological Design Guide: Rolling Bearings, Types and Load life capabilities

Bearing Problems & Navigation

Fundamentals of Bearings with Rolling Elements

Bearings In Maths

Fundamentals of bearings

HYDRAULIC PRESS VS BALL BEARINGS! Which will EXPLODE first?

How Train Wheels Work 🤔

What Is Bearing? All Types Of Bearings And Their Usage And Working

Maths Help: Finding Bearings - VividMath.com

Maths Tips 4 #maths #mathematics #bearings #gcsemaths #gcsemathsrevision

AmazingChina: Assemble Giant Roller Bearing

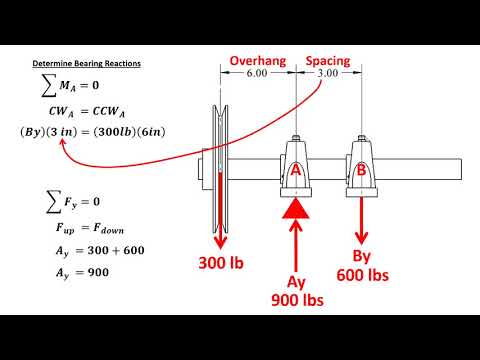

Rolling Element Bearings: Choosing Ball Bearing Size for Life & Reliability in Axial & Radia...

Video Bearing Load Calculations

Anti friction bearing basics & type of bearings

How To Get Rid Of A Backlash Quickly And Effectively #Shorts

Комментарии

0:10:14

0:10:14

0:10:00

0:10:00

0:05:28

0:05:28

0:08:51

0:08:51

0:00:16

0:00:16

0:23:45

0:23:45

0:11:13

0:11:13

0:01:32

0:01:32

0:00:06

0:00:06

0:34:19

0:34:19

0:18:40

0:18:40

0:48:39

0:48:39

0:05:22

0:05:22

0:05:35

0:05:35

0:01:19

0:01:19

0:00:33

0:00:33

0:10:57

0:10:57

0:05:55

0:05:55

0:00:47

0:00:47

0:00:59

0:00:59

1:14:39

1:14:39

0:07:09

0:07:09

0:06:22

0:06:22

0:00:32

0:00:32