filmov

tv

🚂 Emergency Railway Track Repair ⛏️

Показать описание

This is a film showing an emergency track repair to restore Canadian National Railway's mainline service following a collision of two freight trains.

__________________________________________________________________

__________________________________________________________________

🚂 Emergency Railway Track Repair ⛏️

RAILWAY TRUCK REPAIR | Calgary 2023

Efficient Railway Track Repair 🛤

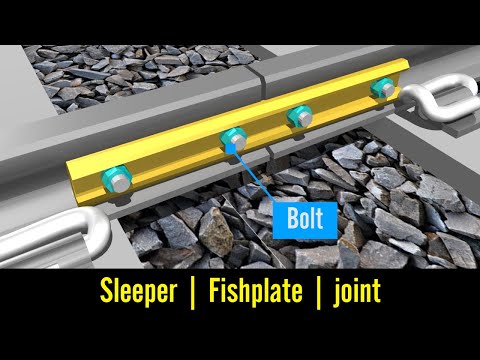

Railway Track Components | #Sleeper | #Ballast | #Joint | #fastening system | #Joggled Fishplate

Emergency railway track repair #asmr #shorts

TRRS 547: Railroad Rail Replacement

Team work for maintaining railway track !#railway #maintains #constructionsite #constructionlife

AMAZING RAILWAY TRACK LAYING MACHINE, TRACK RENEWAL TRAIN TECHNOLOGY, MODERN RAILWAY CONSTRUCTION

How to Look After Our Railway _ UK Railway Maintenance - Edge Hill Depot Network Rail

What Is a Railway Twist Fault on the Railway? The Best Complete Intro Guide

Railway track maintenance | Calgary, Canada.

Hypnotic Process of Clearing Ballast on 1000 Mile Rail Tracks

railway track repair #shorts September 6, 2022

how to repair railway track #shortsfeed #shorts

Railway Signaling Systems Insights Post Coromandel Express Accident

emergency railway track repair

Blasting down bad track Doubleheader on the ND&W Railway (Maumee and Western)

Emergency railway track welding repair #emergency #railway #track #attachment

Railway track maintenance part 1

Railway Track repair🔥🔥🔥🔥🔥🔥

Railway Track🛤️ 🛠️Emergency Repair ⚒️ #ytshorts #travel#train

How to repair a Pakistan Railway track Hindi /urdu new vedio 2022

railway line repair work in emergency @constructionworksite

Thermite welding process for joiningrailway tracks #indian #railway #welding

Комментарии

0:06:12

0:06:12

0:28:43

0:28:43

0:00:16

0:00:16

0:03:48

0:03:48

0:00:21

0:00:21

0:26:19

0:26:19

0:00:13

0:00:13

0:10:12

0:10:12

0:06:04

0:06:04

0:10:04

0:10:04

0:02:19

0:02:19

0:08:45

0:08:45

0:00:13

0:00:13

0:00:17

0:00:17

0:06:54

0:06:54

0:00:28

0:00:28

0:07:24

0:07:24

0:00:15

0:00:15

0:00:16

0:00:16

0:00:22

0:00:22

0:00:16

0:00:16

0:03:41

0:03:41

0:00:15

0:00:15

0:01:00

0:01:00