filmov

tv

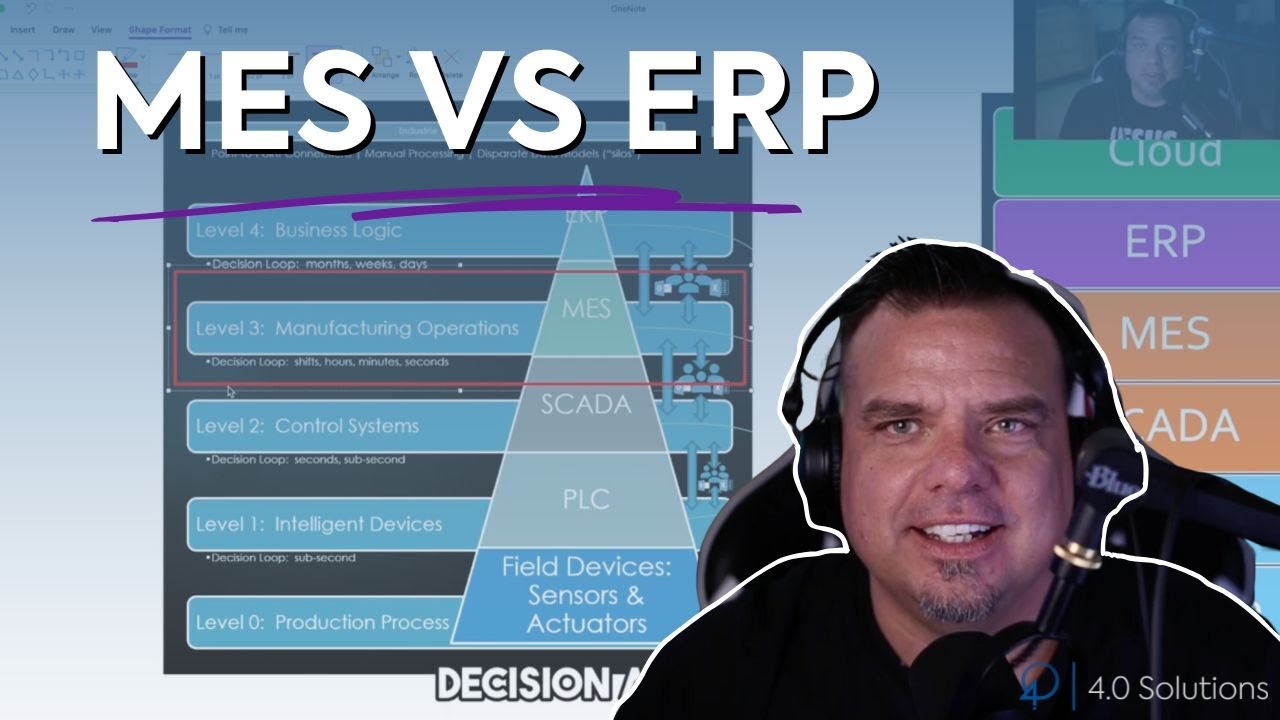

MES vs. ERP: Understanding the Difference and How They Work Together

Показать описание

What’s the difference between MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning)?

Here’s the key: ERP is for planning, while MES is for execution.

*In this video, we break down:*

✅ The core functions of ERP and MES

✅ Why ERP is not the center of your digital universe

✅ How MES bridges the gap between planning and execution

✅ Decision loops for ERP (months to quarters) vs. MES (minutes to shifts)

🎯 *The Takeaway:* MES is where manufacturing happens, turning plans into action while ERP supports strategic planning.

📅 Ready to learn more? *Join our 8-Week MES Bootcamp starting January 7th, 2025!*

🔗 *Learn more and sign up here*

🔔 Don’t forget to like, subscribe, and hit the notification bell for more insights from our MES series!

#MES #ERP #DigitalTransformation #ManufacturingExcellence #Industry40

Here’s the key: ERP is for planning, while MES is for execution.

*In this video, we break down:*

✅ The core functions of ERP and MES

✅ Why ERP is not the center of your digital universe

✅ How MES bridges the gap between planning and execution

✅ Decision loops for ERP (months to quarters) vs. MES (minutes to shifts)

🎯 *The Takeaway:* MES is where manufacturing happens, turning plans into action while ERP supports strategic planning.

📅 Ready to learn more? *Join our 8-Week MES Bootcamp starting January 7th, 2025!*

🔗 *Learn more and sign up here*

🔔 Don’t forget to like, subscribe, and hit the notification bell for more insights from our MES series!

#MES #ERP #DigitalTransformation #ManufacturingExcellence #Industry40

MES vs. ERP: Understanding the Difference and How They Work Together

What is MES? Manufacturing Execution Systems

MES vs. ERP: how do they differ and why is it so important to integrate both systems?

MES vs. ERP: Understanding the Key Differences - Ep. 8

3 Key Differences Between ERP & MES Systems

MES to ERP Communications Explained!

iRIMAU vs ERP & MES

MES vs ERP? MES Landscape #2

What is Manufacturing Execution System (MES)?

MES 2 min pour comprendre : MES vs ERP

Was ist MES

What's the Difference Between, MES, ERP, and Manufacturing Analytics?

What is Manufacturing Execution System MES | Epicor ERP

12.2 ERP & MES

What is ERP System? (Enterprise Resource Planning)

What is MES?

ERP, PLM, CRM, CPQ, MES eine neue Perspektive - Business IT endlich verstehen

ERP System - Was ist das eigentlich?

3 Winning Smart Manufacturing Stories 2017: PLM vs. ERP, Brewery MES, and Proving ROI

Main Difference between ERP Package S/w & MES S/w. We can Say MES is production execution S/w..

ERP + MES - Menschen, Maschinen und Software in der digitalen Fabrik

Wat is het verschil tussen MES en ERP?

What is the Automation Pyramid?

12.1 Einleitung (MES-/ERP-Systeme)

Комментарии

0:15:18

0:15:18

0:07:34

0:07:34

0:01:08

0:01:08

0:11:55

0:11:55

0:01:59

0:01:59

0:09:00

0:09:00

0:05:32

0:05:32

0:05:38

0:05:38

0:06:14

0:06:14

0:03:03

0:03:03

0:01:52

0:01:52

0:01:03

0:01:03

0:03:27

0:03:27

0:11:13

0:11:13

0:01:18

0:01:18

0:05:32

0:05:32

0:07:18

0:07:18

0:03:23

0:03:23

0:54:38

0:54:38

0:04:28

0:04:28

0:29:35

0:29:35

0:10:25

0:10:25

0:07:54

0:07:54

0:09:51

0:09:51