filmov

tv

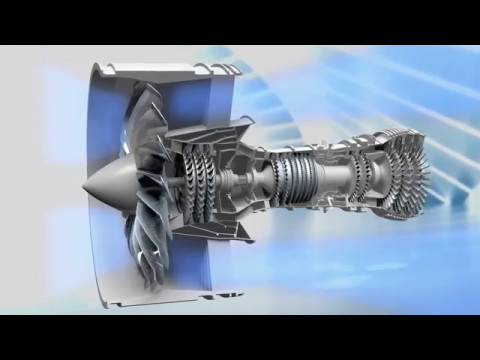

Jet Engine Air Oil Separator

Показать описание

Turbine engines are expensive and powerful. The Air Oil separators they use are also expensive and powerful. Let's have a look, shall we?

Jet Engine Air Oil Separator

How is an Aircraft Engine Lubricated? | Engine Oil System in 3 minutes | Aviation Notes | Faults

How Jet Engines Work

Jet Engine Bleed Air - Aircraft Gas Turbine Engines #15

Aircraft Systems - 06 - Oil System

What Does An Air Oil Separator Do | Ask K&N

305-396-303-0 RING AIR/OIL SEPARATOR CFM56-3

Dana Power Technologies | Victor Reinz® MultiTwister™ Air Oil Separator System

How a PT6A engine works.

The BEST TURBOPROP explanation video! By Captain Joe and PRATT & WHITNEY

Jet Questions 56

Oil Filter Animation | Kelly Clark Automotive Specialists

Czyszczenie odmy w Fiat Bravo 2 1,4 T-JET 150KM - demontaż odmy olejowej (AIR/OIL SEPERATOR)

Fuel Flow - T700-GE-701C ENGINE HD

Engine Breather (Oil/Air Separator) - ULpower 350is - Zenith 750 Cruzer Kit Plane Build

The Difference Between Catch Cans And Air/Oil Separators!

How Oil Water Separators Work

AOS (AIR/OIL SEPARATOR) SERVICE on your Fiat 500 Abarth (or any 1.4l turbo engine) - HOW TO!

Kenny's Thoughts on Oil Separators for Your Mustang

Compressor Atlas Copco

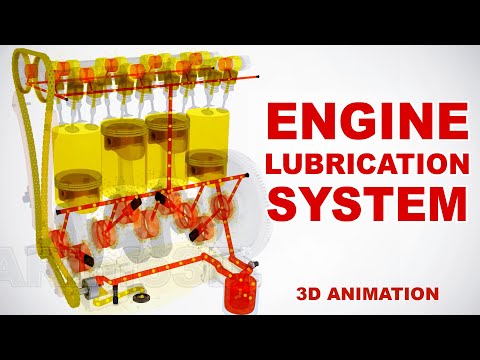

Engine lubrication system / How does it work? (3D animation)

Aviation Turbine Oils

Centrifugal Oil Filter | Centrifuge Oil Cleaner | Working Principle

Mustang Install: Ford Performance Passenger Side Oil-Air Separator Kit

Комментарии

0:34:09

0:34:09

0:03:33

0:03:33

0:03:13

0:03:13

0:16:50

0:16:50

0:02:03

0:02:03

0:01:15

0:01:15

0:00:34

0:00:34

0:03:34

0:03:34

0:01:25

0:01:25

0:13:16

0:13:16

0:24:57

0:24:57

0:00:18

0:00:18

0:15:37

0:15:37

0:00:38

0:00:38

0:30:11

0:30:11

0:02:20

0:02:20

0:00:17

0:00:17

0:09:52

0:09:52

0:02:06

0:02:06

0:00:31

0:00:31

0:06:41

0:06:41

0:00:43

0:00:43

0:01:22

0:01:22

0:02:25

0:02:25