filmov

tv

Pulse Tube Cryocooler (Part 4) - Valve Controlled

Показать описание

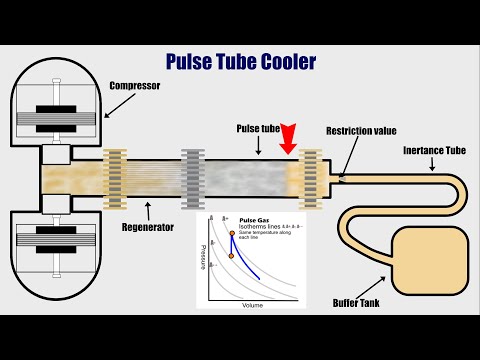

This is the 4th part in my video series on designing/building/testing a pulse-tube cryocooler in an attempt to create low enough temperatures to liquify nitrogen (-196C or 77K). In this video, i'll be investigating an entirely different type of pulse tube that uses two valves - one connected to a compressor and another vented to the atmosphere - to create the pressure oscillations in the pulse tube. This is known as a "Gifford-McMahon" (GM)cycle, and is more commonly used in a refrigeration cycle with a moving displacer, but can also be found in use with pulse tubes.

The GM cycle is less efficient than using a piston (stirling-type) to generate pressure oscillations, but has the advantage that it's cheaper and easier to build, since it can be coupled with a variety of different compressors and matching acoustic impedance is not neccesary. GM-type cycles typically operate at a COP of under 5% of Carnot, whereas advanced stirling-type coolers can approach 30% of Carnot. Despite this, GM cycles are the primary type used in terrestrial applications, such as cryocoolers in labs and production

facilities

where modest quantities (under 10L per day) of LN2 are required. Despite the increased energy consumption, this configuration is typically cheaper to install/maintain than stirling cycle coolers, which are usually reserved for aerospace applications, like being mounted onboard sattelites or missiles to cool optics.

For the valve assembly, i used a pair of solenoid valves activated by MOSFETs which could have their timing controlled by an arduino with a front panel display, allowing me to know the exact timing I dialed in, which was very convenient for repeatability. Real GM cycle coolers use a rotary valve connected to a motor inside the pressurized assembly, which is more reliable than solenoid valves.

The entire assembly runs at around 0.5 hz. Typical commercial units range between 1-2 hz, in contrast to stirling cycle units, which can operate anywhere from 20 hz to 100 hz. However, pressure ratios are typically much higher on a GM unit, ranging from 2-3 with a baseline pressure typically from 10-30 atmospheres, whereas pressure ratios on stirling units are usually in the neighborhood of 1.1-1.3. Most GM units will have a high pressure side around 200-400 psi and a low pressure side from 50-200 psi, depending on the cold head and compressor being used.

The lowest temperature i achieved running on compressed air was -83C, but I didn't consider this a valid result, because I wasn't able to repeat it. The lowest repeatable temperatures were in the low 70's, basically matching the performance of my previous stirling-type pulse tube. Considering that the power input required was close to 1 kW, compared to the previous design's power of ~120W max., it's clear that this setup is far less efficient.

One of the major sources of inefficiency is the fact that my low-pressure side is simply connecting to the atmosphere, rather than being connected back to the compressor in a closed loop. This is because my current compressor isn't hermetically sealed, and not meant to operate with input pressures over 1 atm. With my high side pressure at 100 psi, theoretically, the most efficient low side pressure would be somewhere between 40-60 psi.

In the next part of this series, I'll be generating hydrogen and using it as a working fluid instead of air, with a closed-loop system running off a hermetically sealed fridge compressor. This will dramatically increase internal heat transfer, making the whole system more powerful and efficient, and should bring me much closer to my goal of -196C.

Part I:

Part II:

Part III:

Music Used:

Kevin MacLeod - Lobby Time

Kevin MacLeod - George Street Shuffle

The GM cycle is less efficient than using a piston (stirling-type) to generate pressure oscillations, but has the advantage that it's cheaper and easier to build, since it can be coupled with a variety of different compressors and matching acoustic impedance is not neccesary. GM-type cycles typically operate at a COP of under 5% of Carnot, whereas advanced stirling-type coolers can approach 30% of Carnot. Despite this, GM cycles are the primary type used in terrestrial applications, such as cryocoolers in labs and production

facilities

where modest quantities (under 10L per day) of LN2 are required. Despite the increased energy consumption, this configuration is typically cheaper to install/maintain than stirling cycle coolers, which are usually reserved for aerospace applications, like being mounted onboard sattelites or missiles to cool optics.

For the valve assembly, i used a pair of solenoid valves activated by MOSFETs which could have their timing controlled by an arduino with a front panel display, allowing me to know the exact timing I dialed in, which was very convenient for repeatability. Real GM cycle coolers use a rotary valve connected to a motor inside the pressurized assembly, which is more reliable than solenoid valves.

The entire assembly runs at around 0.5 hz. Typical commercial units range between 1-2 hz, in contrast to stirling cycle units, which can operate anywhere from 20 hz to 100 hz. However, pressure ratios are typically much higher on a GM unit, ranging from 2-3 with a baseline pressure typically from 10-30 atmospheres, whereas pressure ratios on stirling units are usually in the neighborhood of 1.1-1.3. Most GM units will have a high pressure side around 200-400 psi and a low pressure side from 50-200 psi, depending on the cold head and compressor being used.

The lowest temperature i achieved running on compressed air was -83C, but I didn't consider this a valid result, because I wasn't able to repeat it. The lowest repeatable temperatures were in the low 70's, basically matching the performance of my previous stirling-type pulse tube. Considering that the power input required was close to 1 kW, compared to the previous design's power of ~120W max., it's clear that this setup is far less efficient.

One of the major sources of inefficiency is the fact that my low-pressure side is simply connecting to the atmosphere, rather than being connected back to the compressor in a closed loop. This is because my current compressor isn't hermetically sealed, and not meant to operate with input pressures over 1 atm. With my high side pressure at 100 psi, theoretically, the most efficient low side pressure would be somewhere between 40-60 psi.

In the next part of this series, I'll be generating hydrogen and using it as a working fluid instead of air, with a closed-loop system running off a hermetically sealed fridge compressor. This will dramatically increase internal heat transfer, making the whole system more powerful and efficient, and should bring me much closer to my goal of -196C.

Part I:

Part II:

Part III:

Music Used:

Kevin MacLeod - Lobby Time

Kevin MacLeod - George Street Shuffle

Комментарии

0:17:11

0:17:11

0:18:24

0:18:24

0:19:06

0:19:06

0:04:40

0:04:40

0:18:17

0:18:17

0:00:14

0:00:14

0:01:09

0:01:09

0:06:02

0:06:02

0:04:00

0:04:00

0:01:00

0:01:00

0:06:36

0:06:36

0:03:07

0:03:07

0:00:16

0:00:16

0:03:01

0:03:01

0:01:01

0:01:01

0:00:46

0:00:46

0:00:46

0:00:46

0:00:16

0:00:16

0:15:01

0:15:01

0:01:21

0:01:21

0:00:24

0:00:24

0:00:30

0:00:30

0:00:11

0:00:11

0:12:57

0:12:57