filmov

tv

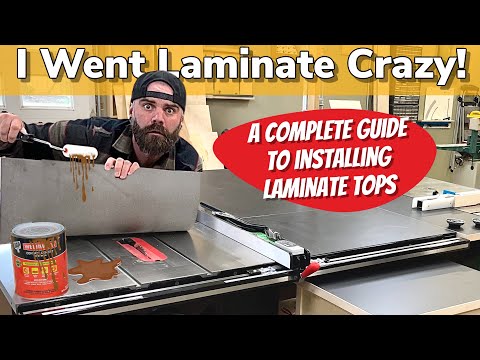

How to: Laminate - Glue Plywood Together to Create Thicker Sheets (NO CLAMPS)

Показать описание

Showing you how I go about Laminating / Glueing 2 Plywood sheets together to make a very sturdy and thicker sheet of Plywood. Perfect to be used as a workbench top or a desktop table.

If you have any questions please leave them in the comments and I'll do my best to get back to them as soon as I can.

**office renovation video coming soon**

🛠 Subscribe To Keep Making:

📨 Share with a friend:

📺 Watch My Most Recent Upload:

Other Places Where you can find me:

If you have any questions please leave them in the comments and I'll do my best to get back to them as soon as I can.

**office renovation video coming soon**

🛠 Subscribe To Keep Making:

📨 Share with a friend:

📺 Watch My Most Recent Upload:

Other Places Where you can find me:

2 Easy Ways to Laminate Wood // Glue Selection

Contact Adhesive - How to fix a laminate end strip to worktop

How To Cut And Glue Laminate // DIY FORMICA Accent Wall Or Countertop

How to: Laminate - Glue Plywood Together to Create Thicker Sheets (NO CLAMPS)

How To Laminate Plywood | Beginner's Guide

Tuskbond One - Bonding laminate to MDF

How to Install Sheet Laminate on a Countertop

Table laminate using contact adhesive (VT-328)

Plywoods laminating with petg film for interior decoration china new technology #machine =#wood

How to make perfect laminate glass with adhesive Eva film?

How to Glue a Laminate Flooring Plank

HOW TO REMOVE LAMINATE GLUE CHEAPLY D.I.Y

DIY how to make Formica laminate glue applicator from scrap formica

How to use PUR glue to laminate the board

Bonding Loose Laminate with an Iron

How to Install Laminate on Your Worktop || DIY Laminate Work Surfaces

DIY LAMINATOR TIPS | How to laminate at home

Simple Technique for Gluing Thin Panels

Un gluing formica or laminate

How to laminate door skins | PVAC gluing machine and automatic cold pressing line

How to Fix Gaps in Flooring!!! (Laminate, LVP, Engineered wood)

How I laminate my eyebrows ✨ ABH - Brow Freeze & Brow Pen Hudabeauty - Faux Filter Concealer

How to apply Laminate to Plywood

How to Laminate OCA glue on LCD

Комментарии

0:08:16

0:08:16

0:01:06

0:01:06

0:07:51

0:07:51

0:06:26

0:06:26

0:05:28

0:05:28

0:00:46

0:00:46

0:10:51

0:10:51

0:00:57

0:00:57

0:00:45

0:00:45

0:00:48

0:00:48

0:03:04

0:03:04

0:00:54

0:00:54

0:03:07

0:03:07

0:01:29

0:01:29

0:02:00

0:02:00

0:31:23

0:31:23

0:04:49

0:04:49

0:01:47

0:01:47

0:01:53

0:01:53

0:00:46

0:00:46

0:05:54

0:05:54

0:00:31

0:00:31

0:05:24

0:05:24

0:00:16

0:00:16