filmov

tv

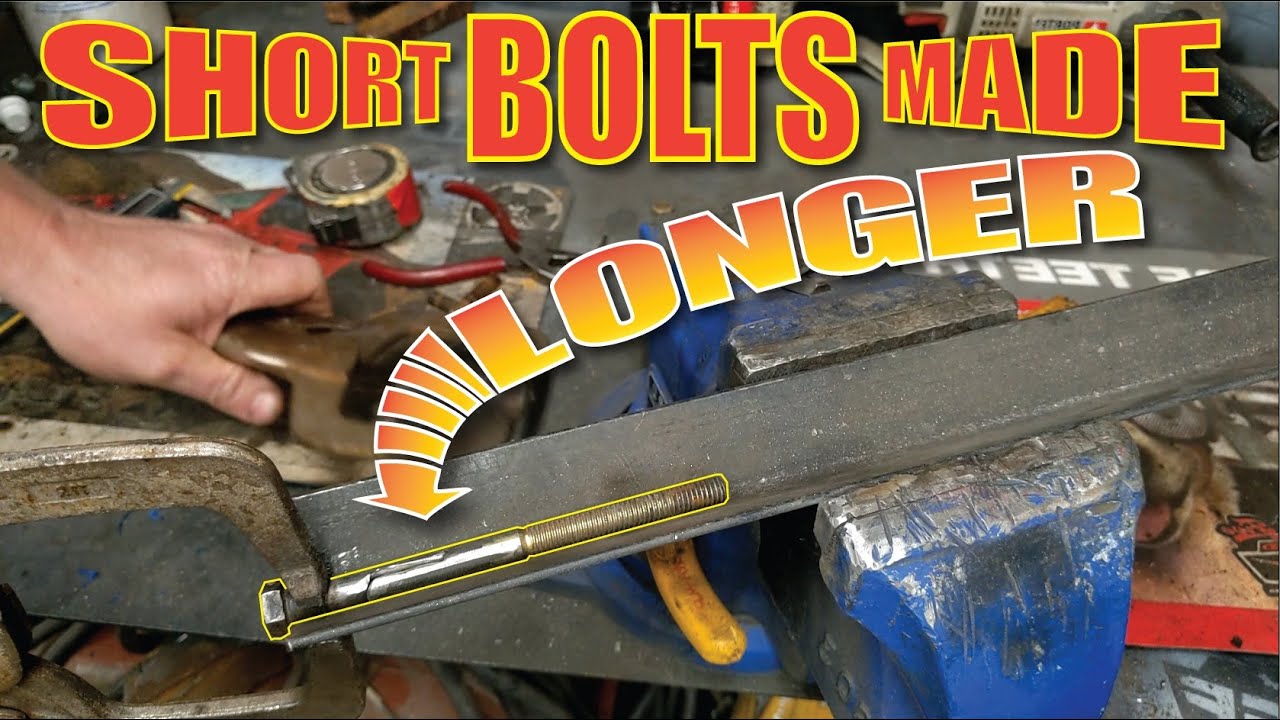

How to make BOLTS longer - Lengthen Extend Bolts -

Показать описание

Any length of bolt is now achievable. This same technique is used in shortening car axle shafts that handle 100's of horsepower.

Tools I used in the video:

VIDEO THOUGHTS

Mig it and be done is seconds. You can also Flux Core, Oxy acetylene, or even stick weld if it's big enough.

Don't Quench:

Why? because you will never match the factory hardening process in your garage and will worse case make the bolt fragile/brittle. Sure allowing it to cool slowly naturally is going to make the metal soft, but that's like saying I only want soft rocks thrown at me. It's still strong/hard. It will just bend or stretch easier vs snapping. The shaft of any give bolt is over 25% stronger than the thread area as it has 25%+ larger surface area. Not having it tempered properly is not going to reduce the strength more than this.

I ask nothing of my viewers but awesome people are constantly asking how they can support the channel:

OR

STAY UP TO DATE BETWEEN PROJECTS

Tools I used in the video:

VIDEO THOUGHTS

Mig it and be done is seconds. You can also Flux Core, Oxy acetylene, or even stick weld if it's big enough.

Don't Quench:

Why? because you will never match the factory hardening process in your garage and will worse case make the bolt fragile/brittle. Sure allowing it to cool slowly naturally is going to make the metal soft, but that's like saying I only want soft rocks thrown at me. It's still strong/hard. It will just bend or stretch easier vs snapping. The shaft of any give bolt is over 25% stronger than the thread area as it has 25%+ larger surface area. Not having it tempered properly is not going to reduce the strength more than this.

I ask nothing of my viewers but awesome people are constantly asking how they can support the channel:

OR

STAY UP TO DATE BETWEEN PROJECTS

Комментарии

0:08:17

0:08:17

0:00:26

0:00:26

0:15:52

0:15:52

0:00:29

0:00:29

0:00:44

0:00:44

0:00:13

0:00:13

0:00:56

0:00:56

0:02:04

0:02:04

0:00:55

0:00:55

0:15:08

0:15:08

0:00:12

0:00:12

0:07:17

0:07:17

0:03:46

0:03:46

0:00:51

0:00:51

0:00:59

0:00:59

0:10:55

0:10:55

0:00:24

0:00:24

0:19:25

0:19:25

0:02:31

0:02:31

0:00:23

0:00:23

0:05:50

0:05:50

0:02:24

0:02:24

0:00:47

0:00:47

0:05:33

0:05:33