filmov

tv

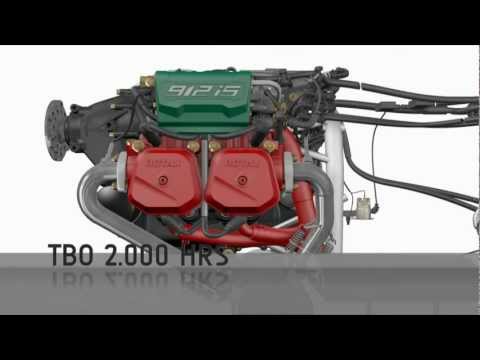

What Makes The Rotax 915 Aircraft Engine So Special?

Показать описание

Use the referral code: "MOJOGRIP" to get 60 days free.

One of the reasons I chose to build a Sling Tsi is because of the engine it’s built around; a Rotax 915 turbo charged engine. Turbo is not often used for single piston engine aircraft, but when you fly behind one, it’s a great extra boost of power.

The Rotax 915 is not only turbo charged, but it’s also a fully managed engine with an electonic ECU system. Makes this engine a FADEC: full authority digital engine control. Your fuel flow, rpm, engine speed, all managed by a computer.

This engine also takes car gas which is cheaper than 100 ll. Matter of fact, Rotax recommends to use car gas if you can find it.

Maintenance is nothing unusual. You have your oil change at 50 -100 hours, at 200 hours you change the spark plugs and at 600 hours you check your gearbox.

There’s so much to love about the Rotax 915. The video discusses more cool features in detail.

Thank you to all of our Sponsors

Music:

One of the reasons I chose to build a Sling Tsi is because of the engine it’s built around; a Rotax 915 turbo charged engine. Turbo is not often used for single piston engine aircraft, but when you fly behind one, it’s a great extra boost of power.

The Rotax 915 is not only turbo charged, but it’s also a fully managed engine with an electonic ECU system. Makes this engine a FADEC: full authority digital engine control. Your fuel flow, rpm, engine speed, all managed by a computer.

This engine also takes car gas which is cheaper than 100 ll. Matter of fact, Rotax recommends to use car gas if you can find it.

Maintenance is nothing unusual. You have your oil change at 50 -100 hours, at 200 hours you change the spark plugs and at 600 hours you check your gearbox.

There’s so much to love about the Rotax 915. The video discusses more cool features in detail.

Thank you to all of our Sponsors

Music:

Комментарии

0:12:17

0:12:17

0:02:44

0:02:44

0:03:55

0:03:55

0:03:55

0:03:55

0:01:03

0:01:03

0:00:59

0:00:59

0:11:12

0:11:12

0:09:28

0:09:28

0:07:37

0:07:37

0:00:51

0:00:51

0:13:11

0:13:11

0:00:31

0:00:31

0:00:51

0:00:51

0:09:54

0:09:54

0:07:08

0:07:08

0:03:30

0:03:30

0:09:39

0:09:39

0:00:07

0:00:07

0:04:21

0:04:21

0:12:59

0:12:59

0:03:25

0:03:25

0:04:38

0:04:38

0:02:15

0:02:15

0:21:24

0:21:24