filmov

tv

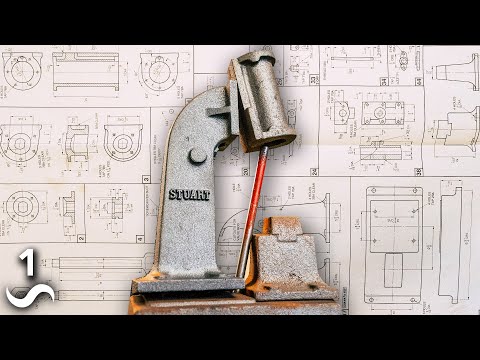

FIXING A 1900's STEAM HAMMER! Pt. 3

Показать описание

Instagram:

Alec: @alecsteele

My name is Alec Steele. I am a blacksmith, amateur machinist and all-round maker of all-things metal. We make videos about making interesting things, learning about craft and appreciating the joy of creativity. Great to have you here following along!

MUSIC:

-signing up at this link supports the show!

- signing up at this link supports the show!

------------------------------------------------

AMAZON AFFILIATE LINKS TO GEAR I LIKE, buying here supports us:

--------------

FIXING A 1900's STEAM HAMMER! pt.1

FIXING A 1900's STEAM HAMMER! Pt. 2

FIXING A 1900's STEAM HAMMER! Pt. 12

FIXING A 1900's STEAM HAMMER! Pt. 17

FIXING A 1900's STEAM HAMMER! Pt. 5

FIXING A 1900's STEAM HAMMER! Pt. 3

FIXING A 1900's STEAM HAMMER! Pt.16

FIXING A 1900's STEAM HAMMER! Pt. 10

FIXING A 1900's STEAM HAMMER! Pt. 8

FIXING A 1900's STEAM HAMMER! Pt. 14

FIXING A 1900's STEAM HAMMER! Pt. 13

FIXING A 1900's STEAM HAMMER! Pt. 4

FIXING A 1900's STEAM HAMMER! Pt. 7

FIXING A 1900's STEAM HAMMER! Pt. 11

FIXING A 1900's STEAM HAMMER! Pt. 6

FIXING A 1900's STEAM HAMMER! Pt.15

FIXING A 1900's STEAM HAMMER! Pt. 9

Steam hammer,drop hammer, forging hammer power hammer driven by steam

Forging a Revolution: The Incredible History of the Steam Hammer

I DROVE A 1900's STEAM LOCOMOTIVE!

Making a Steam Power Hammer! Part 1

FIXING THE 300LBS POWER HAMMER!!! Part 1

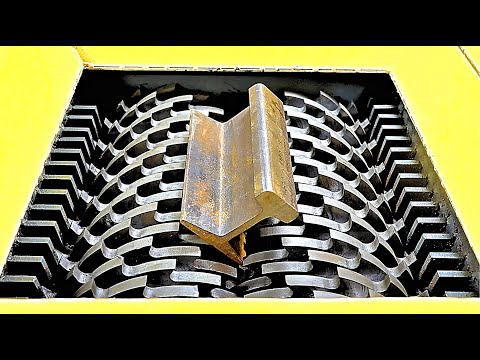

Train tracks VS Shredder !Who will win ? Will the shredder be damaged? Release the pressure!

What Happened to the Crew of This Train? | Last Moments

Комментарии

0:14:56

0:14:56

0:18:30

0:18:30

0:16:14

0:16:14

0:23:14

0:23:14

0:16:38

0:16:38

0:18:25

0:18:25

0:22:18

0:22:18

0:16:19

0:16:19

0:16:40

0:16:40

0:17:15

0:17:15

0:18:37

0:18:37

0:15:14

0:15:14

0:16:39

0:16:39

0:17:48

0:17:48

0:16:17

0:16:17

0:15:43

0:15:43

0:14:21

0:14:21

0:01:19

0:01:19

0:13:11

0:13:11

0:23:13

0:23:13

0:12:22

0:12:22

0:19:57

0:19:57

0:03:47

0:03:47

0:05:29

0:05:29