filmov

tv

CNC Machining History: Punch tapes EXPLAINED

Показать описание

Ever wondered how punch tapes could deliver so much information to machines? In this video, @GCodeTutor Marc Cronin explains to us how they work.

Punch tapes used to be the only way to store programming information back in the days. When "fed" to the machines, these strings of paper would deliver the information necessary to operate the program.

The name "punch tape" comes from the holes punched on the tape that will be used to convert programming information into binary data.

Punch tapes typically look like strings of paper with multiple lines of holes. Each line will feature either 5 or 8 holes. Each of these holes represents a bit and each line represents a byte.

Once fed, the machine will use a light system to convert the holes pattern into information.

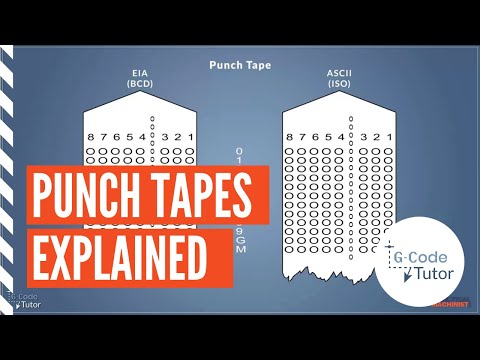

There are two standards of tapes engineers used to work with: EIA, also known as BCD, and the ASCII, which is known as ISO.

Although identical in the looks, the two tape standards there's one main characteristic that differentiates them: EIA system tapes will feature an odd number of holes on each line while ASCII system tapes will feature an even number of holes on each line.

The reason this is done this way is to help the tape reader to identify an error and alert the operator.

Although machinists nowadays don't have to deal with punch tapes, knowing how they work can help understand the difference between high-level programming and low-level programming. G-Code is considered high-level programming language because it converts into 0s and 1s that the machine's CPU can read.

Have you ever worked with punch tapes or seen them in your machine shop? Share your experience in the comments!

Stay tuned for more machining videos!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Recommended CNC programming books:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Practical Machinist is the largest and most engaged #metalworking community across the web. With more than 160,000 registered members and 200,000+ social media followers, Practical Machinist is the easiest way to learn new techniques, get answers quickly, and discuss common challenges with your peers. Visit Practical Machinist today to join the community and start connecting with your peers.

#gcode #machining #cnc

Punch tapes used to be the only way to store programming information back in the days. When "fed" to the machines, these strings of paper would deliver the information necessary to operate the program.

The name "punch tape" comes from the holes punched on the tape that will be used to convert programming information into binary data.

Punch tapes typically look like strings of paper with multiple lines of holes. Each line will feature either 5 or 8 holes. Each of these holes represents a bit and each line represents a byte.

Once fed, the machine will use a light system to convert the holes pattern into information.

There are two standards of tapes engineers used to work with: EIA, also known as BCD, and the ASCII, which is known as ISO.

Although identical in the looks, the two tape standards there's one main characteristic that differentiates them: EIA system tapes will feature an odd number of holes on each line while ASCII system tapes will feature an even number of holes on each line.

The reason this is done this way is to help the tape reader to identify an error and alert the operator.

Although machinists nowadays don't have to deal with punch tapes, knowing how they work can help understand the difference between high-level programming and low-level programming. G-Code is considered high-level programming language because it converts into 0s and 1s that the machine's CPU can read.

Have you ever worked with punch tapes or seen them in your machine shop? Share your experience in the comments!

Stay tuned for more machining videos!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Recommended CNC programming books:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Practical Machinist is the largest and most engaged #metalworking community across the web. With more than 160,000 registered members and 200,000+ social media followers, Practical Machinist is the easiest way to learn new techniques, get answers quickly, and discuss common challenges with your peers. Visit Practical Machinist today to join the community and start connecting with your peers.

#gcode #machining #cnc

Комментарии

0:08:59

0:08:59

0:00:31

0:00:31

0:04:44

0:04:44

0:00:15

0:00:15

0:09:46

0:09:46

0:07:55

0:07:55

0:00:15

0:00:15

0:04:59

0:04:59

0:00:32

0:00:32

0:06:50

0:06:50

0:00:49

0:00:49

0:00:23

0:00:23

0:10:36

0:10:36

0:00:16

0:00:16

0:00:16

0:00:16

0:06:49

0:06:49

0:00:10

0:00:10

0:03:59

0:03:59

0:12:04

0:12:04

0:02:15

0:02:15

0:00:46

0:00:46

0:00:16

0:00:16

0:00:11

0:00:11

0:04:54

0:04:54