filmov

tv

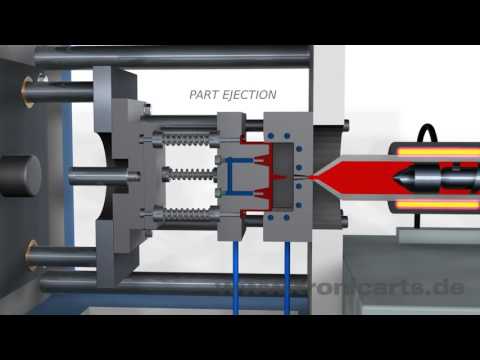

INJECTION & Casting System for 3D Printers

Показать описание

We built an injection system and a different workflow for all makers. Now you can produce wide variety of different parts with your 3D Printer without size restrictions.

It's not closed material. You can use your own resins too.

==========

Flovv Specs:

Flow: 1 kg/mins at highest setting on Rigid Material

Adjustable Flow

15sec Cleaning Sequence

2x 1 Gallon Component Tanks

In Tank Mixer for Color Change and Mixing Before Injection

1 Gallon Cleaning Fluid Tank

Device Size

Width:455mm

Depth: 305mm

Height: 6200mm

Weight:10kgs

Electrical: 110VAC/22VAC 1kW (max)

Materials: Rigid, Flexible(5 shore A,20 shore A, 50 shore A), Rigid Foam, Flexible Foam(Coming Soon)

Accessories

Mold Release

Mold Prying Tools

5x spare Nozzles

Flovv-e Specs:

Build Volume: 12”x12”x16”

oversized print bed to reduce warping on full plate builds

Chassis: Stainless steel and aluminium

Printing Speed: 300mm/s

HGX Extruder

Device Size

Width:770mm

Depth: 550mm

Height: 860mm

Weight:55kg

Electrical Consumption: 110VAC/22VAC 1.5kW(max)

All of our chemicals are US made. Flovv and Flovv-e is engineered and manufactured in US.

0:00 Intro

0:42 What is Reaction Injection Molding?

1:20 How did we do it?

1:35 Injection System

1:56 Color Change/Accessories

2:06 Cleaning System

3:10 Rigid Material

3:26 Overmolding

3:55 Structural RIM

4:18 Flexible Part

4:41 Foam

5:02 DaaS

5:20 Flovv-e

5:44 Outro

#3dprinting #polyurethane #moldingmaking #casting #injectionmolding

It's not closed material. You can use your own resins too.

==========

Flovv Specs:

Flow: 1 kg/mins at highest setting on Rigid Material

Adjustable Flow

15sec Cleaning Sequence

2x 1 Gallon Component Tanks

In Tank Mixer for Color Change and Mixing Before Injection

1 Gallon Cleaning Fluid Tank

Device Size

Width:455mm

Depth: 305mm

Height: 6200mm

Weight:10kgs

Electrical: 110VAC/22VAC 1kW (max)

Materials: Rigid, Flexible(5 shore A,20 shore A, 50 shore A), Rigid Foam, Flexible Foam(Coming Soon)

Accessories

Mold Release

Mold Prying Tools

5x spare Nozzles

Flovv-e Specs:

Build Volume: 12”x12”x16”

oversized print bed to reduce warping on full plate builds

Chassis: Stainless steel and aluminium

Printing Speed: 300mm/s

HGX Extruder

Device Size

Width:770mm

Depth: 550mm

Height: 860mm

Weight:55kg

Electrical Consumption: 110VAC/22VAC 1.5kW(max)

All of our chemicals are US made. Flovv and Flovv-e is engineered and manufactured in US.

0:00 Intro

0:42 What is Reaction Injection Molding?

1:20 How did we do it?

1:35 Injection System

1:56 Color Change/Accessories

2:06 Cleaning System

3:10 Rigid Material

3:26 Overmolding

3:55 Structural RIM

4:18 Flexible Part

4:41 Foam

5:02 DaaS

5:20 Flovv-e

5:44 Outro

#3dprinting #polyurethane #moldingmaking #casting #injectionmolding

Комментарии

0:05:54

0:05:54

0:02:59

0:02:59

0:00:17

0:00:17

0:05:21

0:05:21

0:00:27

0:00:27

0:01:05

0:01:05

0:00:26

0:00:26

0:00:18

0:00:18

0:01:00

0:01:00

0:00:25

0:00:25

0:01:35

0:01:35

0:09:37

0:09:37

0:02:12

0:02:12

0:00:41

0:00:41

0:00:21

0:00:21

0:01:53

0:01:53

0:00:52

0:00:52

0:00:30

0:00:30

0:00:41

0:00:41

0:02:07

0:02:07

0:00:14

0:00:14

0:01:29

0:01:29

0:00:42

0:00:42

0:06:30

0:06:30