filmov

tv

Plastic Honeycomb Composite Panels VS Plywood

Показать описание

Lightweight Composite Plastic Honeycomb Panels comparison to plywood for boat repair.

Plastic Honeycomb Composite Panels VS Plywood

Fiberglass PP Honeycomb Panel Test

Deform-Nut Rivet Anchor for Honeycomb and Sandwich Panels

Composite Panels vs Aluminum on a Camper Trailer

18mm Fiberglass PP Honeycomb Wall Panels

Polypropylene honeycomb panels, corrugated plastic honeycomb sheets from China

Sandwich Core Materials Overview - Updated

FRP PP honeycomb sandwich panel

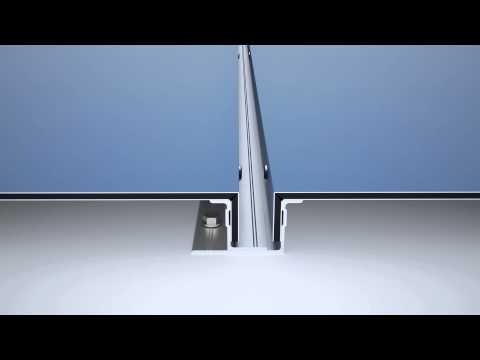

ECONECT-Z™ Aluminum Composite Material Panel System

Sandwich Core Materials

How to easily make Fiberglass Honeycomb Panels

Non woven Fiberglass Honeycomb Core Composite Panels

Working With Honeycomb Structural Panels. Onboard Lifestyle ep.48

Easy Tricks Using Fiberglass Strengthening!

Fiberglass honeycomb composite panel

Fiberglass Composite Panels for RVs

Cheaper honeycomb panel.

PP Honeycomb Sandwich Panel

We supply high quality fiberglass XPS foam RV composite panels

Plastic honeycomb panel cutting machine #honeycomb #Plastic #cutter #cuttingmachine

Aluminum Anti-collision Honeycomb Composite Panel with SPC layer

Carbon Fiber Prepreg With Nomex Honeycomb Core (Spacegrade)

Custom Size Style Carbon Fiber Sandwich Panel Honeycomb Core PMI Foam Core

Plastic honeycomb corrugated sheets, pp honeycomb sheet panel board, polypropylene honeycomb sheet

Комментарии

0:05:18

0:05:18

0:00:16

0:00:16

0:00:56

0:00:56

0:04:40

0:04:40

0:00:26

0:00:26

0:00:21

0:00:21

0:03:07

0:03:07

0:00:16

0:00:16

0:00:19

0:00:19

0:03:01

0:03:01

0:10:58

0:10:58

0:00:16

0:00:16

0:32:39

0:32:39

0:20:08

0:20:08

0:00:10

0:00:10

0:01:36

0:01:36

0:00:14

0:00:14

0:00:24

0:00:24

0:00:07

0:00:07

0:00:14

0:00:14

0:00:21

0:00:21

0:08:35

0:08:35

0:00:12

0:00:12

0:00:18

0:00:18