filmov

tv

3 Simple Rules to troubleshooting ANYTHING.

Показать описание

1. Do the easiest thing first

2. Don't rely on the people that tried and failed prior

3. 90% of problems are between the driver's seat and the steering wheel

Bonus: If it can go wrong, it WILL go wrong. (Murphy's Law)

2. Don't rely on the people that tried and failed prior

3. 90% of problems are between the driver's seat and the steering wheel

Bonus: If it can go wrong, it WILL go wrong. (Murphy's Law)

3 Simple Rules to troubleshooting ANYTHING.

The Simple Solution to Traffic

5 Simple Steps for troubleshooting misbehaving rules in Hubitat Elevation

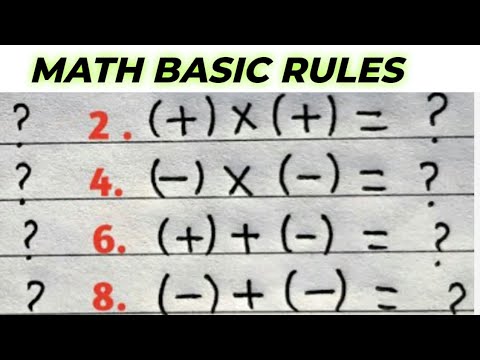

maths + – rules /math basic rules / math tip / problems related on sign / rules positive & negat...

maths + - rules/math rules/maths tips/Problems related on signs/ Rules of Positive & Negative Si...

This tool will help improve your critical thinking - Erick Wilberding

The Golden Path to SpringOne: Five Simple Rules about Problems with Kevin Clark

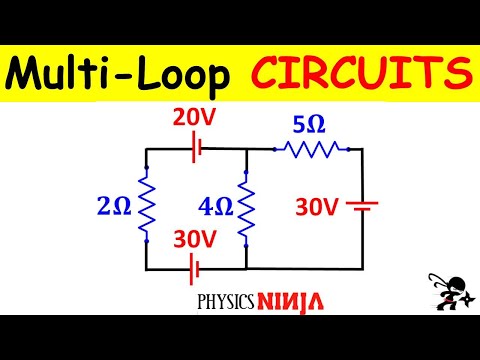

Solving Circuit Problems using Kirchhoff's Rules

Problem Solving Practice Session 1

Trying transition video for the first time 💙😂 || #transformation #transition #shorts #viralvideo...

Bhagavad Gita TOP 3 RULES To Face Any Problems In Life | Swami Mukundananda

Simple rules for cast iron care

5 Common Mistakes When Installing Video Security System

Using Kirchoff's Rules to Solve Circuit Problems with Multiple Batteries

Rules Of Multiplication Of Integers | Sign Problems In Mathematics | Solution By Easy Tricks

SIGNIFICANT FIGURES : How to calculate Significant figures using RULES (Practice Problems -III)

06.02 Kirchhoff's Rules Explained with Practice Problems and Solutions | Learn Through Examples

How to solve genetics problems using Chargaff’s rules

10 Reasons Why You'd FAIL a Plumbing Inspection! | GOT2LEARN

Practice Problems - Rules of Implication

Exponent Rules - PRACTICE PROBLEMS!

Indices: How to Solve Indices Problems||Rules of Indices

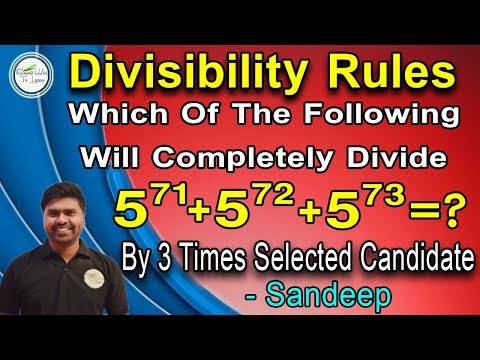

Divisibility Rules Problems Part-3 Which Of The Following Will Completely Divide |Smart Way To Learn

How miscommunication happens (and how to avoid it) - Katherine Hampsten

Комментарии

0:04:18

0:04:18

0:05:14

0:05:14

0:05:09

0:05:09

0:03:56

0:03:56

0:10:12

0:10:12

0:05:20

0:05:20

0:37:29

0:37:29

0:19:19

0:19:19

2:07:20

2:07:20

0:00:15

0:00:15

0:23:11

0:23:11

0:05:40

0:05:40

0:05:07

0:05:07

0:18:07

0:18:07

0:04:38

0:04:38

0:05:59

0:05:59

0:31:01

0:31:01

0:08:32

0:08:32

0:07:36

0:07:36

0:43:03

0:43:03

0:06:05

0:06:05

0:31:23

0:31:23

0:08:51

0:08:51

0:04:33

0:04:33