filmov

tv

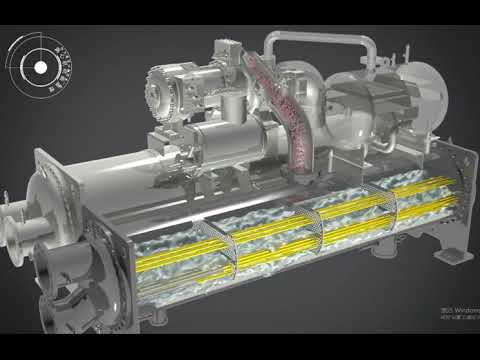

Turbocor Chillers Explained - Oil free magnetic bearing HVAC

Показать описание

Turbocor chiller, learn how turbocor chillers work, the main components and centralised cooling systems. Dual impeller, variable frequency drive, VFD, IGBT, electronic expansion valve EEV, liquid level sensor, air handling unit AHU, fan coil unit FCU, inlet guide vane IGV. Water cooled chiller, air cooled chiller. centralized cooling system. Chilled water, condenser water. Evaporator, condenser.

Learn more about Turbocor® and take the free training program

Danfoss offers a series of online training materials for technicians working with Danfoss Turbocor® oil-free compressors. This series of 12 e-lessons provides a helpful overview of their unique oil-free technology, why it’s different from a conventional compressor, and how to work with it.

Watch these

👋 SOCIALISE WITH US 👋

*******************************

👀 Links - MUST WATCH!! 👀

*******************************

⚡ELECTRICAL ENGINEERING⚡

❄️ CHILLER ENGINEERING ❄️

🌡️ HVAC ENGINEERING 🌡️

⚗️ REFRIGERATION SYSTEMS 🌡️

⚗️ REFRIGERANTS ⚗️

🌊 HYDRONICS 🌊

🔥➡️❄️ HEAT EXCHANGERS 🔥➡️❄️

🎬 DOCUMENTARY 🎬

bmcc industrial engineering igv industrial refrigeration

Learn more about Turbocor® and take the free training program

Danfoss offers a series of online training materials for technicians working with Danfoss Turbocor® oil-free compressors. This series of 12 e-lessons provides a helpful overview of their unique oil-free technology, why it’s different from a conventional compressor, and how to work with it.

Watch these

👋 SOCIALISE WITH US 👋

*******************************

👀 Links - MUST WATCH!! 👀

*******************************

⚡ELECTRICAL ENGINEERING⚡

❄️ CHILLER ENGINEERING ❄️

🌡️ HVAC ENGINEERING 🌡️

⚗️ REFRIGERATION SYSTEMS 🌡️

⚗️ REFRIGERANTS ⚗️

🌊 HYDRONICS 🌊

🔥➡️❄️ HEAT EXCHANGERS 🔥➡️❄️

🎬 DOCUMENTARY 🎬

bmcc industrial engineering igv industrial refrigeration

Комментарии

0:17:36

0:17:36

0:01:26

0:01:26

0:00:45

0:00:45

0:01:33

0:01:33

0:23:19

0:23:19

0:17:38

0:17:38

0:00:18

0:00:18

0:01:34

0:01:34

0:13:18

0:13:18

0:02:50

0:02:50

0:07:40

0:07:40

0:01:20

0:01:20

0:04:58

0:04:58

0:01:07

0:01:07

0:00:08

0:00:08

0:27:47

0:27:47

0:05:19

0:05:19

0:01:34

0:01:34

0:01:12

0:01:12

0:01:11

0:01:11

0:02:49

0:02:49

0:05:16

0:05:16

0:00:11

0:00:11

0:05:15

0:05:15