filmov

tv

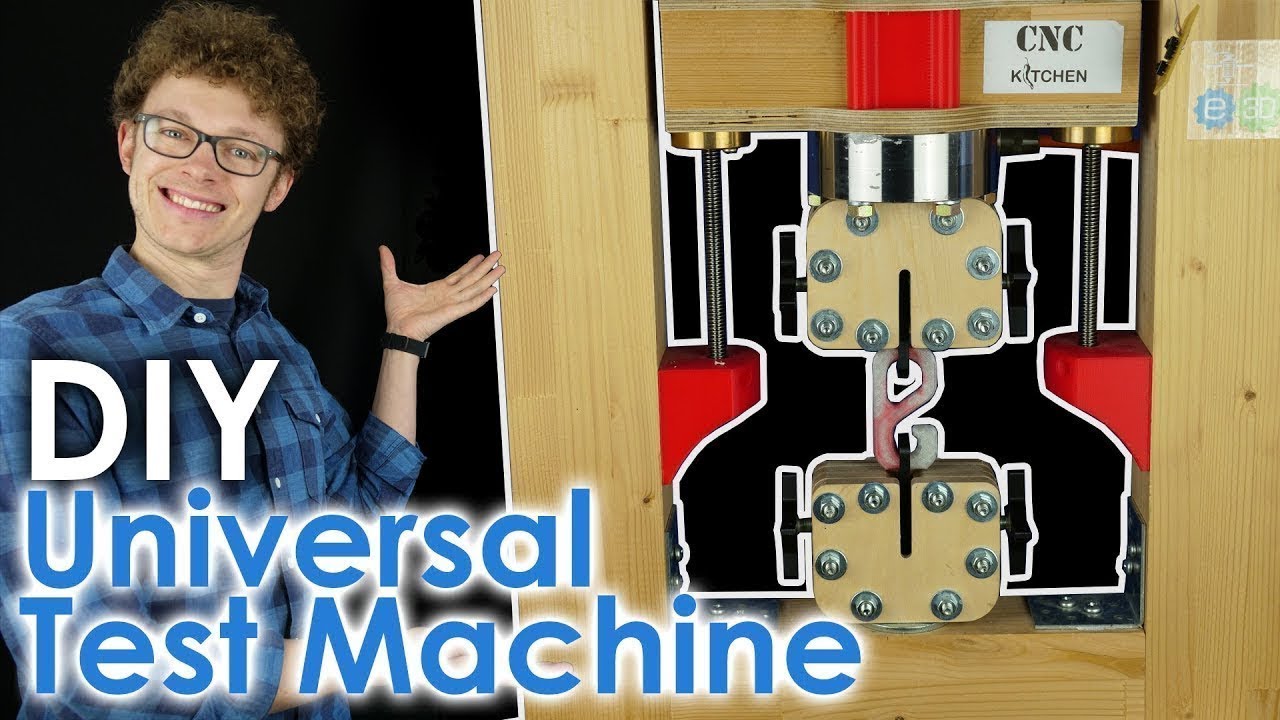

Fully OPEN SOURCE Universal Test Machine!

Показать описание

This is my DIY Universal Test Machine that I use in many of my videos to test the strength of different materials and parts. I finally gathered all the data and made it available open source so that everyone can build on on their own. I'll go through the whole setup and also show how I managed to build an optical extensometer to measure the strain in the test samples.

💚 Support me 💚

Join as a YouTube member!

🎙Check out my PODCAST with Tom Sanladerer

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

Some parts you'll need:

🏆 Do you want to help me cover my running costs? Send me a dollar or two over PayPal, it helps me a lot!

🌼 Even watching the ads before my videos helps me a lot!

Disclaimer: This video was sponsored by Skillshare.

💚 Support me 💚

Join as a YouTube member!

🎙Check out my PODCAST with Tom Sanladerer

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

Some parts you'll need:

🏆 Do you want to help me cover my running costs? Send me a dollar or two over PayPal, it helps me a lot!

🌼 Even watching the ads before my videos helps me a lot!

Disclaimer: This video was sponsored by Skillshare.

Fully OPEN SOURCE Universal Test Machine!

What is a Universal Testing Machine/Tensile Testing Machine?

Tensile Testing of Multiflora Rose Stem Using Instron Universal Testing Machine | Dr. Loay Al-Zube

WDW 50KN 100KN Universal Testing Machine Video

Universal Testing Machine for Compression testing & Tensile testing

universal test machine

HD-B604-S Universal Testing Machine

Test Step Explanations for the Universal Test Machine

Master the Art of Tomcat Penetration Testing in 2025

Universal testing machine in solidworks

universal tensile testing machine software installation operation video

universal testing machine!

Universal Testing Machine #mechanicalengineering #lab

Customized heightening type universal tensile test machine HZ-1004B

How to Choose the Right Tensile Tester (Universal Testing Machine) for your Needs! - 2020

manually writing data to a HDD...kinda #shorts

DYNO UNIVERSAL | UNIVERSAL TESTING MACHINE FOR TENSILE, COMPRESSION, BENDING AND PEELING TESTS

PW Instrument Automatic Universal Material Tensile Testing Machine Production Department

Universal Testing Machine - For Fabric tensile testing

Computer controlled electro hydraulic servo universal testing machine # tensile strength testing mac

Simple universal testing machine- hydraulic press

UNIVERSAL TESTING MACHINE

This $9 Universal ROM Burner is Open Source!

100KN Universal Testing Machine - Copper Bar Tensile Test

Комментарии

0:19:30

0:19:30

0:03:51

0:03:51

0:00:16

0:00:16

0:00:25

0:00:25

0:01:03

0:01:03

0:00:41

0:00:41

0:10:12

0:10:12

0:02:10

0:02:10

0:40:24

0:40:24

0:00:27

0:00:27

0:01:18

0:01:18

0:00:49

0:00:49

0:00:16

0:00:16

0:03:16

0:03:16

0:04:01

0:04:01

0:00:12

0:00:12

0:01:46

0:01:46

0:00:17

0:00:17

0:01:22

0:01:22

0:00:18

0:00:18

0:00:26

0:00:26

0:09:31

0:09:31

0:16:24

0:16:24

0:03:54

0:03:54