filmov

tv

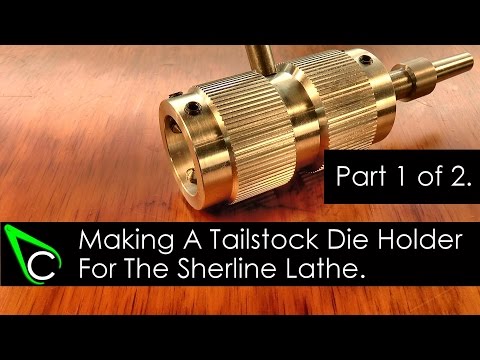

Is this the best Tailstock Die Holder for the home shop machinist?

Показать описание

In this video I make the Tailstock Die Holder from Hemingway Kits. It's got a very interesting clutch mechanism and in my humble opinion is the best available to the home shop machinist or model engineer interested in making their own shop made tools.

Buy the kit from Hemingway;

I talk about the idea of single point threading away from the chuck which I aspire to learn. @joepie221 has some great content on this, check out his video here;

I demonstrate the use of a Noga reversible countersink tool, a tip I picked up from @Blondihacks , Quinn has some great content geared towards the home shop machinist so be sure to check her channel out.

Support the channel;

Buy project plans, 3D printable items and merch!

Check me out on instagram;

Timestamps

0:00 Introduction

0:22 Threading on the lathe

2:51 Hemingway Kit

3:09 Making the clutch cones

6:04 Making the large die holder

9:56 Single point threading

12:09 Making the small die holder

13:10 Internal threading

13:35 Cutting the taper

14:11 Machining the tool body

14:57 Machining offset holes with a Spin Indexer

16:11 Deburring internal holes

16:34 Making the actuator

19:17 Machinable MT3 arbour

19:42 How does the clutch work?

20:58 Dieholder accessory

21:34 Using the die holder

22:02 The best Tailstock Dieholder?

23:38 Conclusion

Buy the kit from Hemingway;

I talk about the idea of single point threading away from the chuck which I aspire to learn. @joepie221 has some great content on this, check out his video here;

I demonstrate the use of a Noga reversible countersink tool, a tip I picked up from @Blondihacks , Quinn has some great content geared towards the home shop machinist so be sure to check her channel out.

Support the channel;

Buy project plans, 3D printable items and merch!

Check me out on instagram;

Timestamps

0:00 Introduction

0:22 Threading on the lathe

2:51 Hemingway Kit

3:09 Making the clutch cones

6:04 Making the large die holder

9:56 Single point threading

12:09 Making the small die holder

13:10 Internal threading

13:35 Cutting the taper

14:11 Machining the tool body

14:57 Machining offset holes with a Spin Indexer

16:11 Deburring internal holes

16:34 Making the actuator

19:17 Machinable MT3 arbour

19:42 How does the clutch work?

20:58 Dieholder accessory

21:34 Using the die holder

22:02 The best Tailstock Dieholder?

23:38 Conclusion

Комментарии

0:24:16

0:24:16

0:00:27

0:00:27

0:00:34

0:00:34

0:00:28

0:00:28

0:27:40

0:27:40

0:08:57

0:08:57

0:18:13

0:18:13

0:00:44

0:00:44

0:15:21

0:15:21

0:23:30

0:23:30

0:04:33

0:04:33

0:29:55

0:29:55

0:16:46

0:16:46

0:37:57

0:37:57

0:10:59

0:10:59

0:14:39

0:14:39

0:11:01

0:11:01

0:32:13

0:32:13

0:40:30

0:40:30

0:14:36

0:14:36

0:17:52

0:17:52

0:09:25

0:09:25

0:03:59

0:03:59

0:01:32

0:01:32